Reliable and convenient diagnostics are a prerequisite for enabling plant and machinery to manufacture efficiently, cost effectively and without interruption. With PVIS, Pilz has developed a universal diagnostics solution for the entire range, from small machines to large plants.

The PVIS OPC Tools are based on an OPC Server. This gives you access to the extended PVIS diagnostics based on standard software interfaces. The PVIS OPC Tools can thus be integrated into almost any environment. That gives you an ideal solution for applications with Pilz products!

Tools for the diagnostic solution PVIS

Diagnostics made easy – With PVIS on OPC/OPC UA Server

Benefits to you

- Saves time when troubleshooting and rectifying faults – the machine can be restarted quickly

- Using the plain text messages, machine operators immediately know which fault has occurred

- Active support for the operator with fault rectification by step-by-step instructions

- PVIS nominates the “responsible parties” for remedying the fault – e.g. a maintenance engineer

- Reduced time between machine standstill and restart

Benefits for machine manufacturers and system integrators

- Pre-defined error messages and step-by-step remedy messages for a large number of safety devices

- Time saving thanks to easy project design

- Easy use due to multi-language predefined messages

- Flexible concept – new messages are easy to add; pre-defined messages are easy to adapt

Benefits for machine operators

- Saves time and money with error messages in plain text

- Practical solution proposals help to get production restarted quickly

- Simple to operate, without any knowledge of programming

- Machine-specific diagnostic solution thanks to an intelligent concept

Always in the picture with the diagnostic solution PVIS – Features

- The diagnostic solution PVIS includes: PVIS OPC Configurator, PVIS OPC Server UA, PVIS ActiveX Control UA, PVIS OPC Server and PVIS ActiveX Control

- Conversion of error numbers from the various automation devices via the OPC Diagnostics Server in text messages and remedies

- Help texts available in many languages – easy to activate by the user in the project

- OPC UA support for the PVIS OPC Diagnostics Server available for the first time from Version 2.0.0

- OPC Server – with the PVIS OPC Tools you can visualise diagnostics messages for several control systems simultaneously (e.g. for the configurable small control systems PNOZmulti and the drive solution PMC)

- Diagnostics messages on several diagnostics devices, access for several PVIS ActiveX Controls to one PVIS OPC Server

Project design features

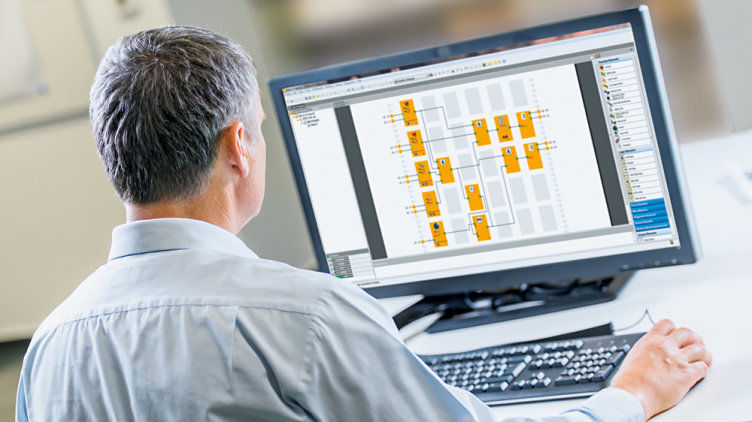

- Diagnostic projects are created with just a few clicks, using familiar programming software (PNOZmulti Configurator, PASmotion)

- Pre-defined plain text messages and remedy messages are available for devices and blocks

- Texts can be copied, adapted or created from new

- Diagnostic messages can be extended based on bit and word information from the control systems

Operational features

- Clear information on the error that has occurred – the operator can act swiftly in the event of an error

- Targeted support for troubleshooting and error rectification – increased scope to act on malfunctions and productivity

- Remedy messages for the safety devices are already pre-defined and stored in the tools

- For later analysis, PVIS stores every event with details of incoming and outgoing times in an "Event Log" ring memory

PVIS event message components

- Plain text message for the event

- Remedy messages for each event (up to eight actions)

- Text-based location information on equipment identifier, scope and responsibility

- Messages are prioritised – the triggering event is always displayed first

Our product range: Diagnostic solution PVIS

Contact

Pilz Ireland

Cork Business and Technology Park, Model Farm Road

Cork

Ireland

Telephone: +353 21 4346535

E-Mail: sales@pilz.ie

Technical Support

Telephone: +353 21 4804983

E-Mail: sales@pilz.ie