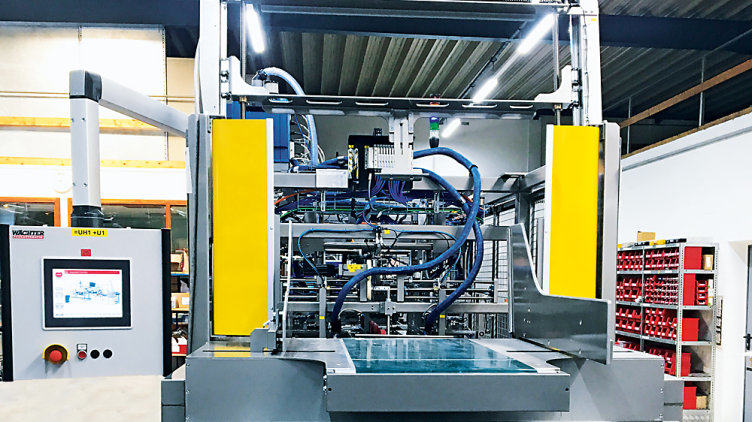

Wächter Packautomatik develops and builds customised packaging solutions. One of them is the powerful case erector Tablomat LE, which efficiently produces up to 30 boxes per minute. The electrosensitive safety gate sensor PSENslock and the safe controller PNOZmulti 2 from Pilz have made the operating concept more flexible and fast format changes can easily be implemented. Flexibility and efficiency are indispensable in the packaging industry, particularly in end-of-line processes.

Clever folding with PSENslock and PNOZmulti 2

More flexibility for control and operation!

So when developing the case erector Tablomat LE a new, sustainable automation and safety concept was included. The requirement was for diagnostic data from the sensors to be available to the machine controller in real-time so that the plant operator can retain a complete overview of the machine status. There are four safety gates on the machine and each use the non-contact safety gate system PSENslock. It performs the safe position monitoring and process guarding. The safety controller PNOZmulti 2 monitors the safety gates and the installed E-STOP pushbutton and guarantees the exchange of diagnostic data via fieldbus module with the PLC. With this efficient solution, fast format changes and fast, simple adaptation of sensor and actuator technology can easily be implemented.

Together with Pilz we have achieved all the stated objectives on the Tablomat LE: The case erector is impressive with its clear, streamlined wiring and it can be reconfigured for new tasks in the shortest possible time. The plant is enjoying virtually trouble-free operation, the operator has a comprehensive overview of the current machine status at all times".

Advantages and benefits of the solution:

- More efficient diagnostics reduces downtimes: The plant operator has a complete overview of the machine status at any time

- The needs-based, transparent automation concept increases safety

- Higher plant availability through more flexibility: Machine can be reconfigured for new tasks in the shortest possible time

About Wächter

For over 43 years Wächter has planned, designed and constructed mainly special purpose machinery in the packaging technology sector with around 200 staff. The performance range also includes the conversion of existing machines and the retrofit of older machines. Wächter has made a name for itself in the food, beverages and flooring industry worldwide.

The products in the application:

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern

Germany

Telephone: +49 711 3409-0

E-Mail: pilz.gmbh@pilz.de

Telephone: +49 711 3409 444

E-Mail: support@pilz.com

Americas

- Canada: +1 888-315-PILZ (315-7459)

- Brazil: + 55 11 4942-7032

- United States (toll-free): +1 877-PILZUSA (745-9872)

- Mexico: +52 55 5572 1300

Europe

- Denmark: +45 74436332

- Belgium: +32 9 321 75 70

- Ireland: +353 21 4804983

- Switzerland: +41 62 889 79 32

- Portugal: +351 229 407 594

- Germany: +49 711 3409 444

- Spain: +34 938497433

- France (toll-free): +33 3 88104000

- Italy: +39 0362 1826711

- Finland: +358 10 3224030 / +45 74436332

- Netherlands: +31 347 320477

- Russia: +7 495 6654993

- Sweden: +46 300 13990 / +45 74436332

- United Kingdom: +44 1536 460866

- Turkey: +90 216 5775552

- Austria: +43 1 7986263-444

Asia Pacific

- China: +86 400-088-3566

- Singapore: +65 6829 2920

- South Korea: +82 31 778 3390

- Taiwan: +886 2 25700068

- New Zealand: +64 9 6345350

- Thailand: +66 210 54613

- Australia (toll-free): +61 3 9560 0621 / 1300 723 334

- Japan: +81 45 471 2281