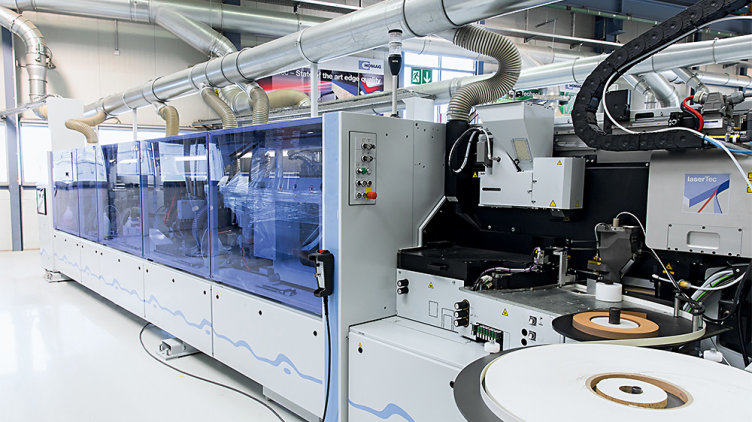

The visible glue joint in furniture may soon be a thing of the past: A LaserTec procedure developed by HOMAG welds edges and panel material without leaving a visible joint.

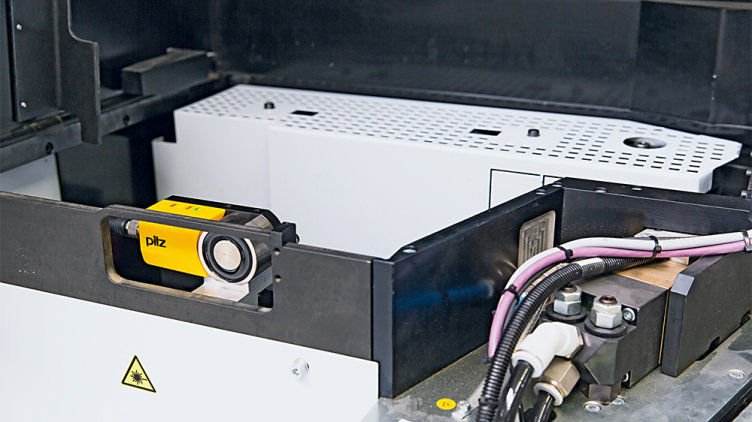

For edge processing in its machines for the furniture industry, HOMAG relies, among other things, on the use of high-power lasers - and therefore also on the freely configurable safety system PNOZmulti from Pilz. So HOMAG avoids potential hazards at the machine operator's workplace.