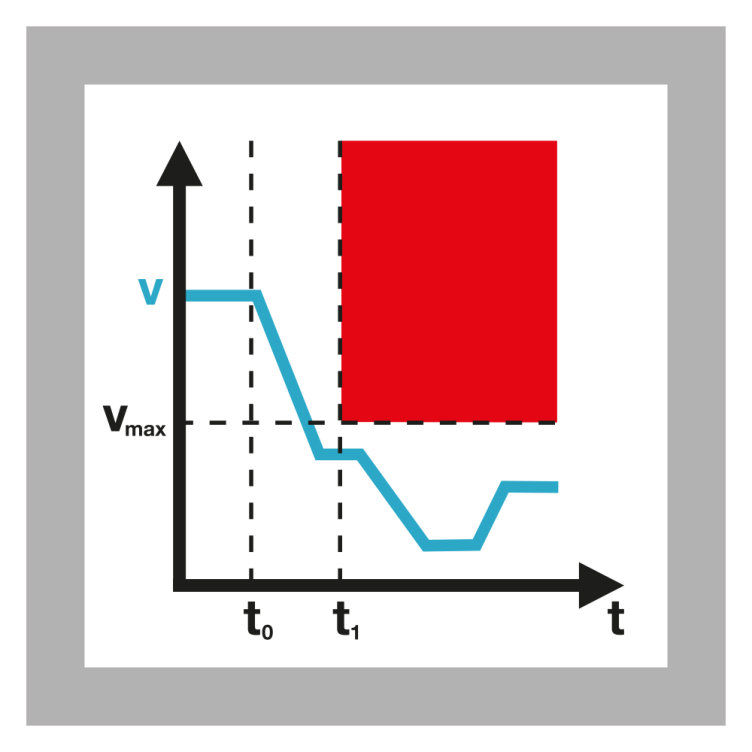

The "safe limited speed (SLS)" in accordance with EN 61800-5-2 is probably the best known safety function. In practice, this safety function is often applied as "safely reduced speed". As a result, a defined transition from the operating speed in automatic mode to the reduced speed in setup mode must be guaranteed. If the monitoring function detects that the limit value has been violated, the drive must be shut down safely. The manner in which the shutdown is achieved depends on the application; it is best to aim for defined braking using the "safe stop" (SS1) function, followed by removal of power.

Safe speed range (SSR) can generally be used for permanent process monitoring. Risks cannot always be eliminated just by limiting the capacity for speeds to suddenly increase. Speed that reduces suddenly as the result of an error can also present a risk. If axes are operating at a defined distance, a speed that drops abruptly on just one of the two axes may create a risk of crushing. These are the cases for which the safe speed range (SSR) function has been defined and developed. This function is used to shut down the relevant axes, thereby eliminating any hazard to the machine operator and the machine.