Flexibility in production is indispensable these days. Plant and machinery must be expanded or retrofitted to react quickly to new market opportunities. Expanding or retrofitting old machinery is often very cost-effective too. Exploit the potential of retrofitting! Pilz is the partner you should consult with when modifying your plant and machinery or having the changes approved. Because even with a retrofit: machinery safety must still be guaranteed.

Retrofit with Pilz

Modernise, expand and retrofit machines.

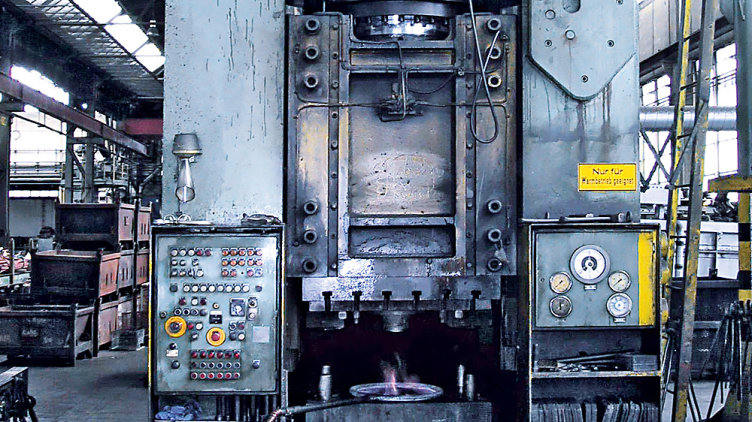

Retrofit to use older machines for longer

Increase your productivity significantly by upgrading your machinery to the state of the art! You need to do this because safety defects can develop on plant and machinery after many years of service. For example, protective measures may become obsolete and be manipulated. The control and drive technology is often outdated while the mechanical components are still fully intact.

Save costs by retrofitting

When retrofits are planned and implemented on a sound basis, older machines can be equipped with the latest electrical, control and safety technology. The costs are considerably less than buying new. The retrofit not only makes the machine safe again, but also increases its productivity and availability. If production is back running efficiently and smoothly, then the retrofit pays for itself in no time.

Pilz can provide support as you modernise your plant and machinery

In the case of a retrofit we conduct a comprehensive analysis of the system and the technology. Only then can we decide what the retrofit must comprise. Potential technical modifications for safe and economical operation as well as applicable directives and standards must be considered and implemented. Retrofitting a machine generally involves a new risk assessment and CE mark.

Pilz specialises in this type of service. Together with you the operator we work out the requirements, inspect the current status of the machine during the safety-related assessment and develop a concept for modifying the machine.

Safe automation with Pilz

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern

Germany

Telephone: +49 711 3409-0

E-Mail: pilz.gmbh@pilz.de

Telephone: +49 711 3409 444

E-Mail: support@pilz.com

Americas

- Canada: +1 888-315-PILZ (315-7459)

- Brazil: + 55 11 4942-7032

- United States (toll-free): +1 877-PILZUSA (745-9872)

- Mexico: +52 55 5572 1300

Europe

- Denmark: +45 74436332

- Belgium: +32 9 321 75 70

- Ireland: +353 21 4804983

- Switzerland: +41 62 889 79 32

- Portugal: +351 229 407 594

- Germany: +49 711 3409 444

- Spain: +34 938497433

- France (toll-free): +33 3 88104000

- Italy: +39 0362 1826711

- Finland: +358 10 3224030 / +45 74436332

- Netherlands: +31 347 320477

- Russia: +7 495 6654993

- Sweden: +46 300 13990 / +45 74436332

- United Kingdom: +44 1536 460866

- Turkey: +90 216 5775552

- Austria: +43 1 7986263-444

Asia Pacific

- China: +86 400-088-3566

- Singapore: +65 6829 2920

- South Korea: +82 31 778 3390

- Taiwan: +886 2 25700068

- New Zealand: +64 9 6345350

- Thailand: +66 210 54613

- Australia (toll-free): +61 3 9560 0621 / 1300 723 334

- Japan: +81 45 471 2281