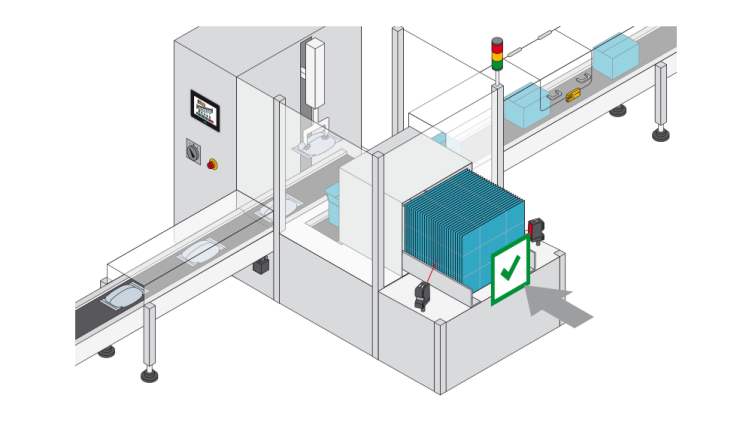

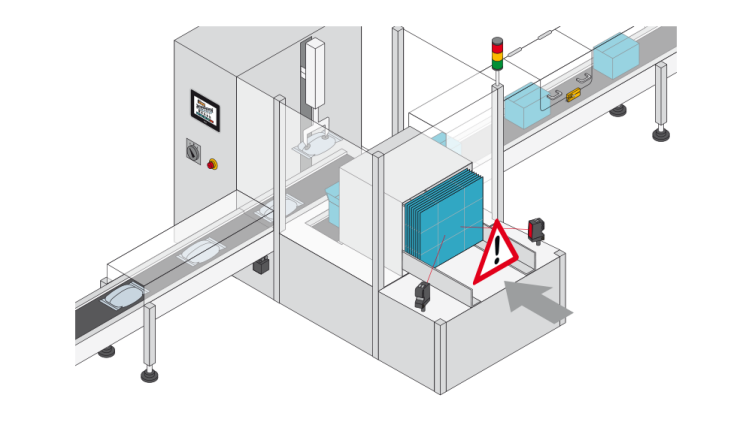

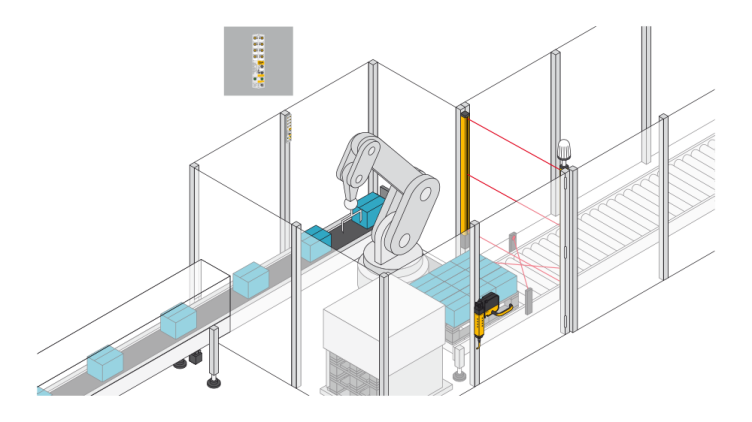

Before the cartoning of the primary packaging, a main application in secondary packaging, the conveyor logistics required to transport goods in and out must also be safeguarded. Dynamic, efficient and flexible solutions for safe automation are required, in order to be competitive.

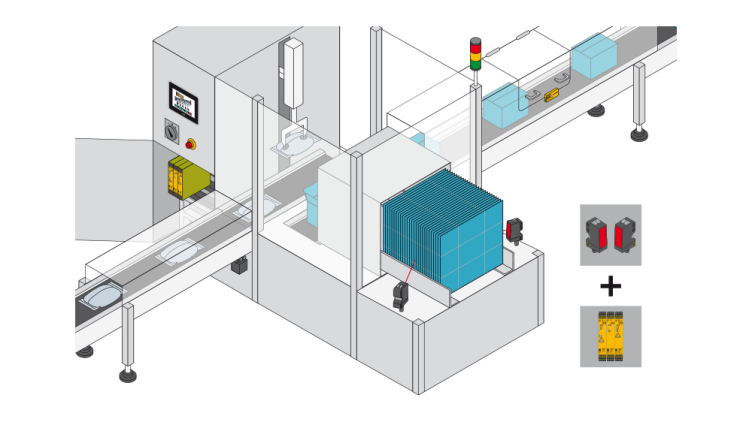

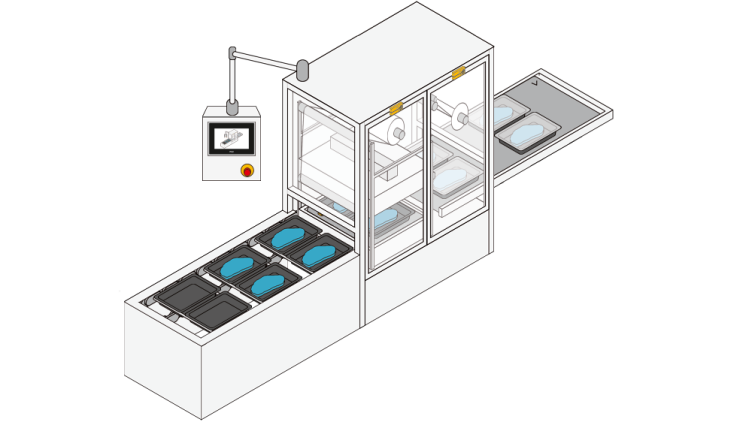

At the exact moment when covers and flaps on plants must be opened, there are other flaps that should be protected, for example to avoid contact with high temperatures such as those that occur while stretch shrink wrapping. Product connectivity and a flexible series connection of safety sensors and control technology not only enable maximum safety for operators, but also ensure the efficiency of the packaging machine.

We offer safe automation solutions for secondary packaging, whether that involves safety sensors, safe small controllers or operating mode selector switches. You can rely on our high level of customer orientation and specialist knowledge of the standards. We're happy to support you with your requirements.