Take advantage of productive area monitoring thanks to PSENscan, including in areas with material infeed and in close proximity to multiple laser scanners.

22 Apr 2021

Safety laser scanner PSENscan: how area monitoring is actually productive!

PSENscan are masters of partial dynamic muting

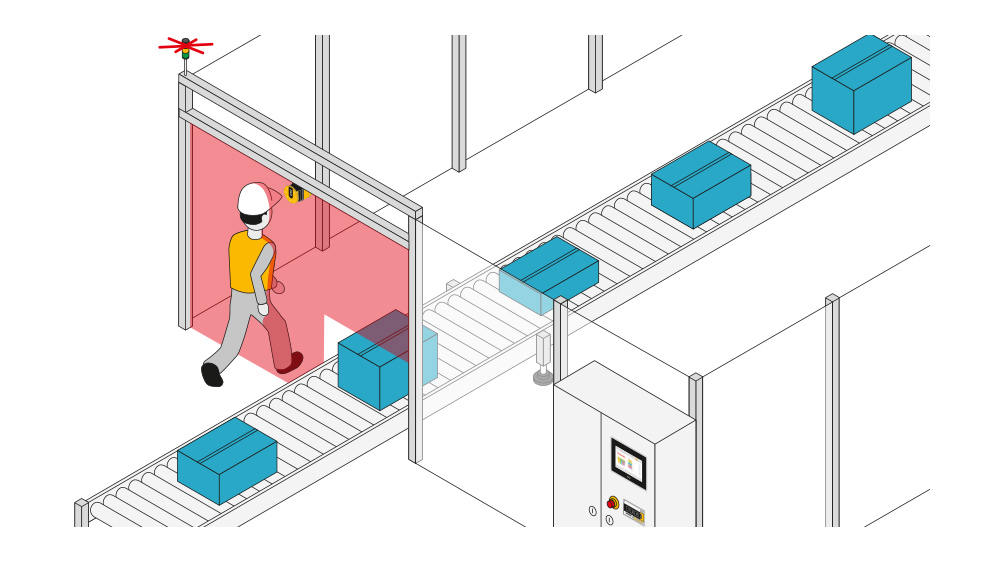

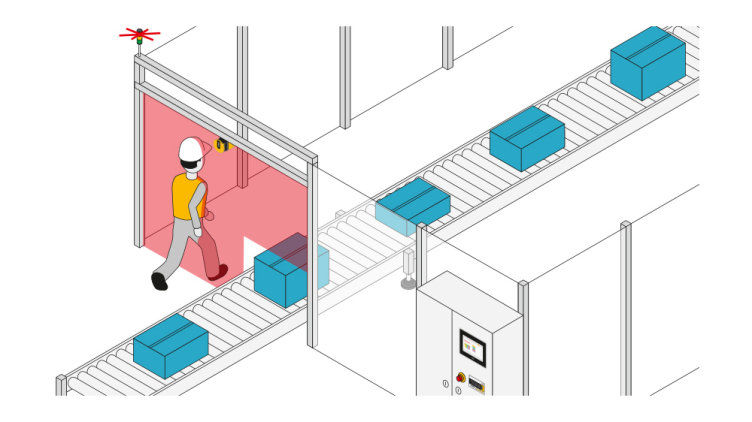

Safety laser scanners PSENscan have partial dynamic muting. This means that partial muting as well as the switching of safety zones are possible. The function is used when feeding in materials. Under certain pre-defined conditions, the transported product is allowed to move within the protected area without the machine coming to a stop. So as well as protecting the operator, high availability is guaranteed at the same time.

Coding ensures there is no interference in the immediate area

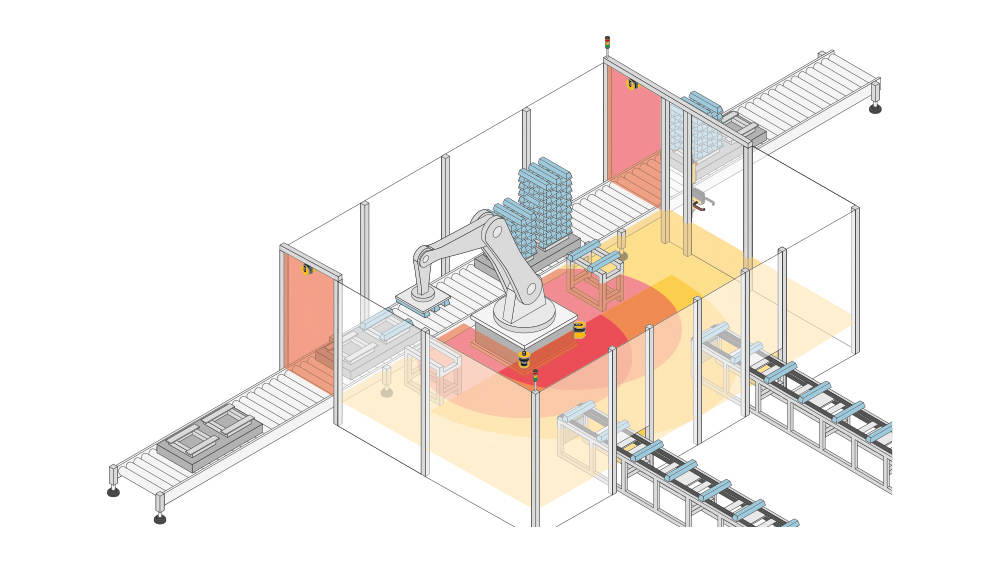

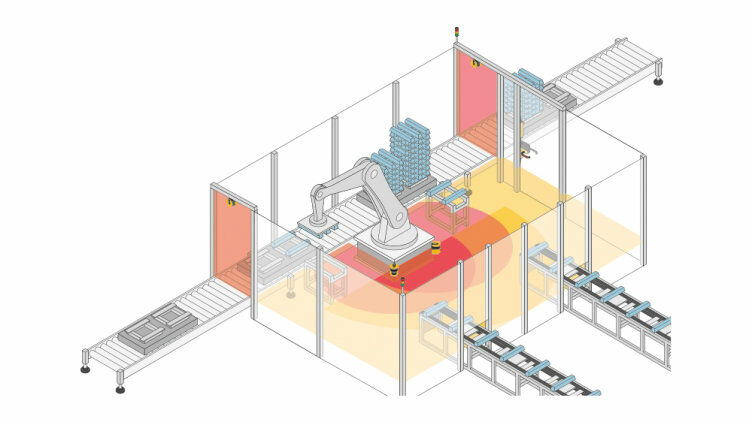

There are also benefits to enjoy from the new beam coding of PSENscan: when a plant operates two safety laser scanners that are not connected in series, mutual interference is excluded. So two safety laser scanners used independently of each other can be operated flexibly in parallel and in close proximity. This increases the plant’s availability and shortens the production time.

Further information:

Pilz Australia Safe Automation

Unit 1, 12-14 Miles Street

Mulgrave, Melbourne, Victoria 3170

Australia

Telephone: +61 3 9560 0621 / 1300 723 334

E-Mail: safety@pilz.com.au