Dynamic muting for greater productivity

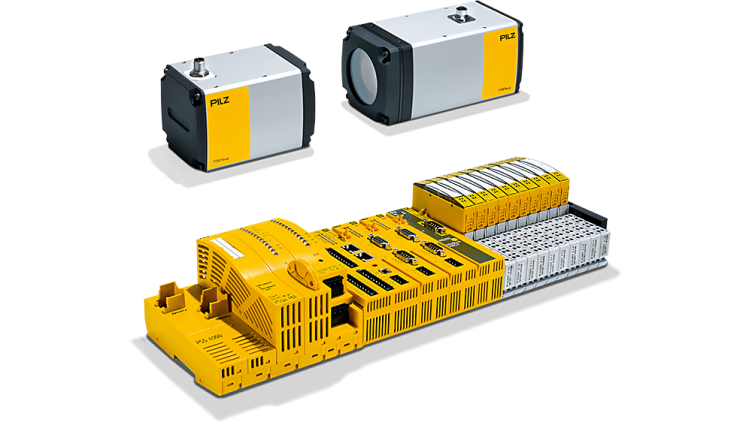

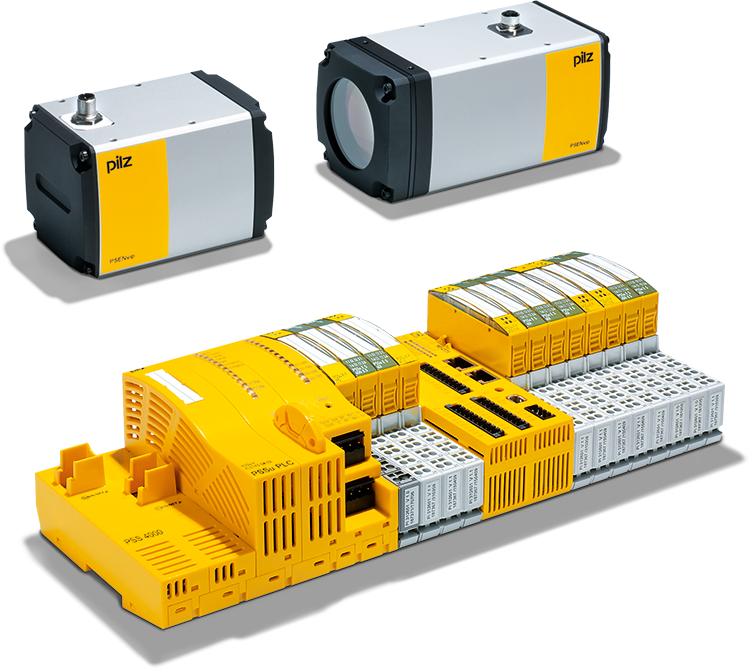

As a complete solution with the Fast Analysis Unit (FAU P) in the automation system PSS 4000, the productive version of the camera-based protection system PSENvip 2 offers dynamic adjustment of the protected field. The speed of the upper tool is continuously adjusted and is only reduced to the lowest level from the detection zone onwards. As a result, it is possible to achieve productivity increases of up to 50 per cent.

With the integrated, certified function block for the productive version, information such as tool class, muting end point or protected field modes is communicated to the PSENvip and safety functions such as position, speed, braking ramp, overrun distances and protected field are monitored. Manual programming is significantly reduced and the application is commissioned quickly and safely.

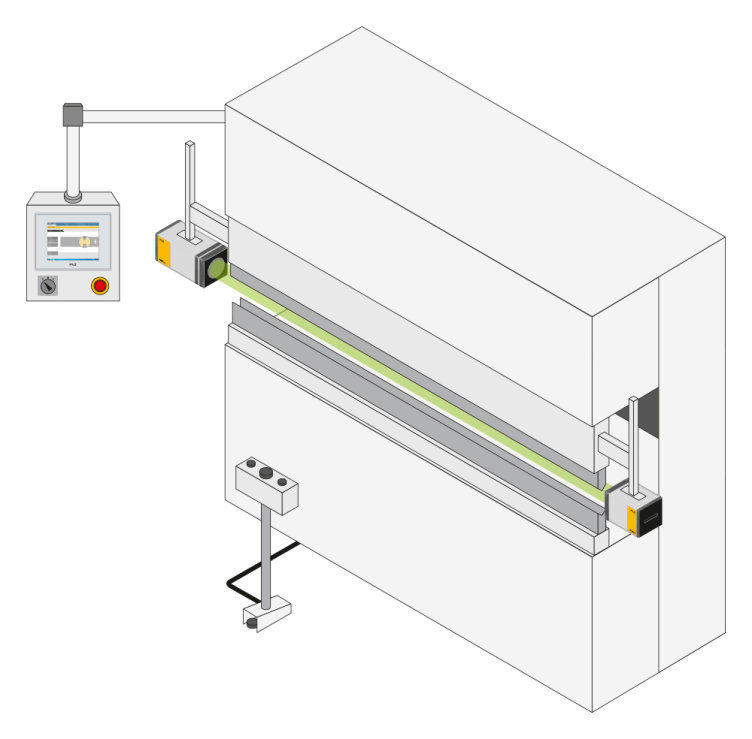

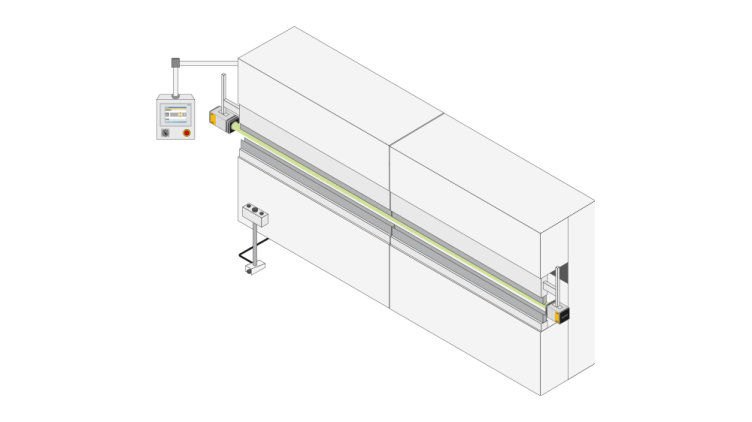

Safe press braking with large tools

Some tools used on press brakes cannot be safeguarded using a conventional solution on account of their size. However, in accordance with the standard EN 12622, each bending line must be safeguarded by a protected field 15 mm in advance, on the operator side. A requirement for complying with this normative specification is that the tool is situated completely within the protection system's field of vision. The camera-based protection systems PSENvip can help in this case.

With the special tools function certified by TÜV Süd, various tool sizes are now classified for the protection systems PSENvip. In tool class 1, protection is in accordance with the standard. However, the camera image for tool classes 2 and 3 can only partially identify the tool in view of its size.

The camera-based protection systems PSENvip can also monitor large tool shapes safely: by raising the switchover point or changing the speed when descending towards the plate. They check the tool contour and assign it to tool class 1, 2 or 3. The established class is communicated to the controller, which then issues enables for class 2 and 3 tools. The switchover points defined by the risk analysis are also monitored.

Important for you the customer: If the parameters for the PSENvip (basic and productive version with PSS 4000) are set correctly, without any safety-related errors, then this is not a significant change in terms of the Equipment and Product Safety Act – the work involved in certification is minimal.

Further information is available in the lexicon entry for "Significant change".