CENELEC standards, Machinery Safety Directive, CE conformity… we have perspective in this standards' jungle. We provide support, from project planning and programming through to documentation and the approvals process. As for drawing up compliant technical documentation for the authorities - you can gladly leave that to us as well.

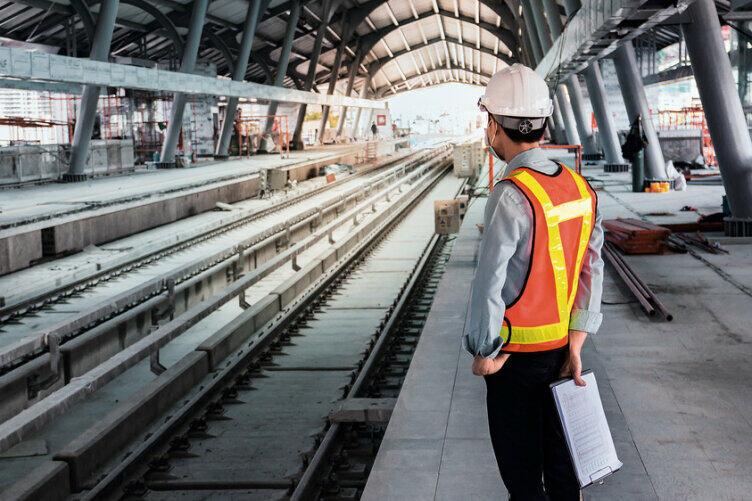

For this purpose, we have tailored our machinery safety and automation services to the railway.

We provide support, from analysis through to implementation of your new safety concept. You get everything from one place and in future have no more worries about your staff's welfare.