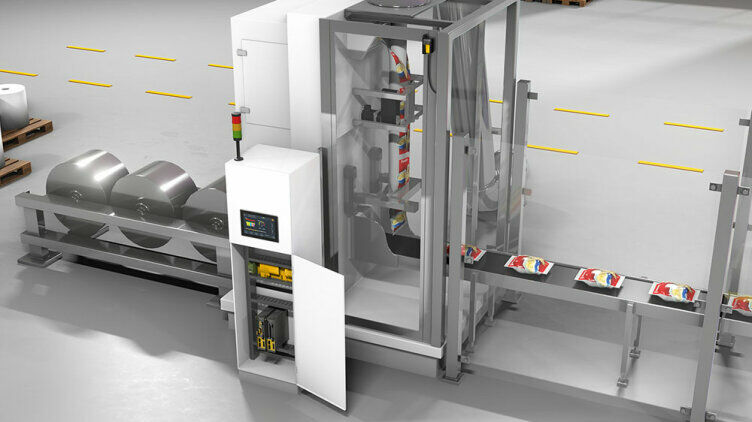

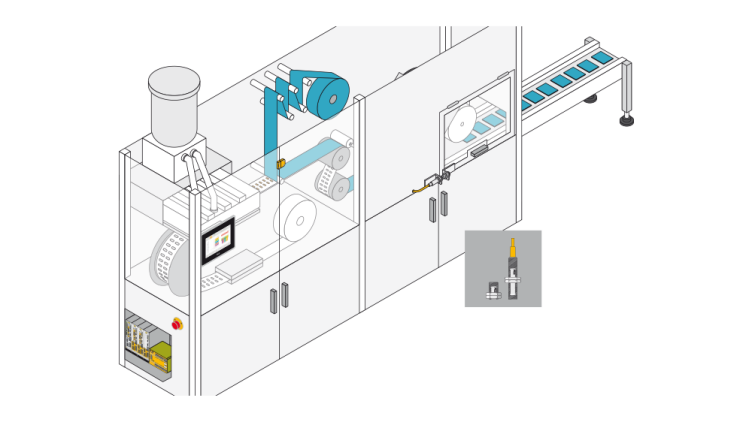

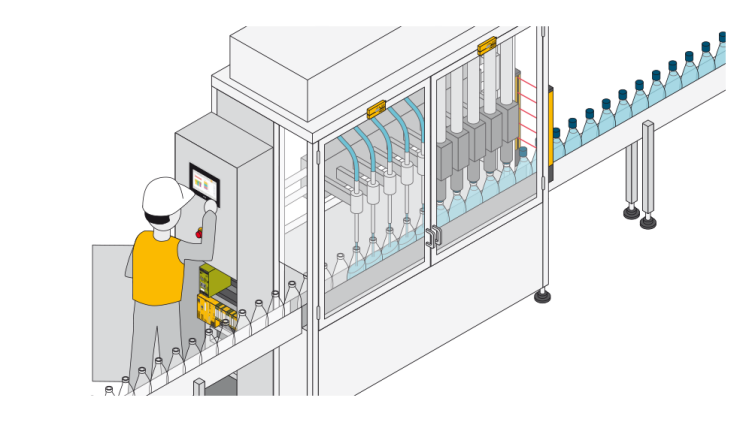

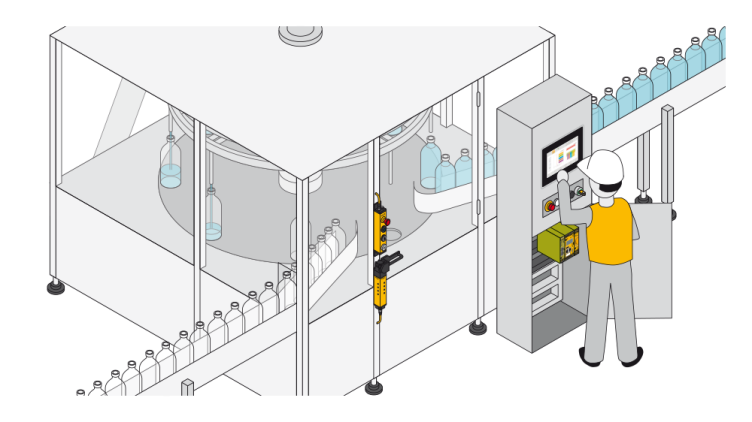

When automating packaging lines in primary packaging, the items packaged are mainly food, drinks, pharmaceutical or even consumer care products. In these industries in particular, the requirements for process protection and hygiene are very high, as the packaging machines and plants are constantly subjected to cleaning processes. Availability and safety are also important criteria on plant and machinery such as bottling plants, forming, filling and sealing machines, as well as in conveyor logistics. All these requirements can be met using our technologies, such as control technology, safety sensors and motion control solutions.

Our focus is on automation, operator safety and the avoidance of unnecessary downtimes for your packaging machine, while maintaining maximum productivity and flexibility.