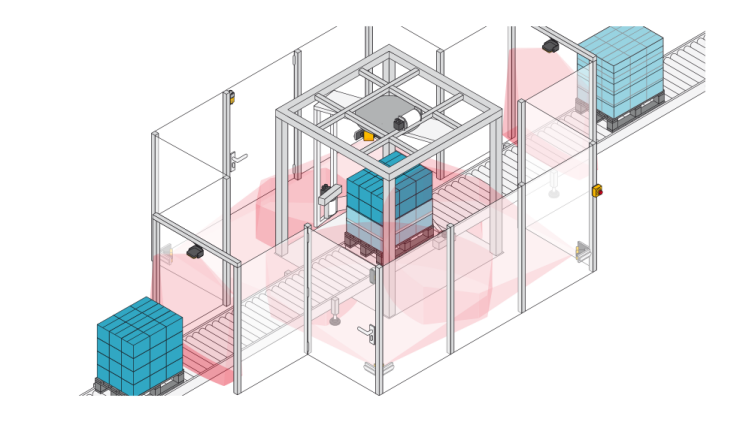

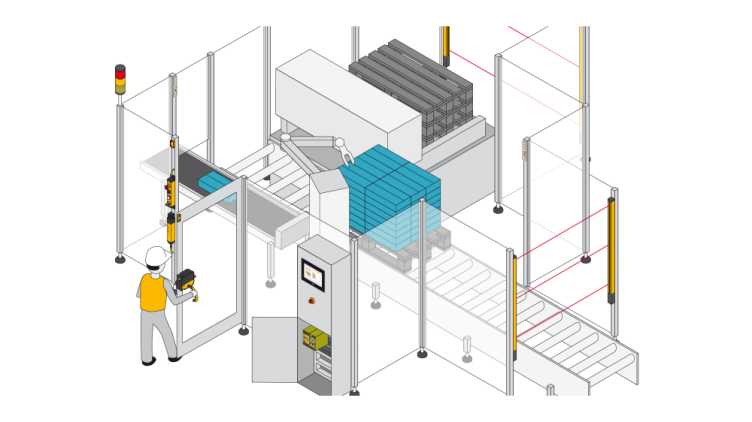

In end-of-line automation in particular, robot applications are frequently used, precisely when processes such as palletising of cartons or secondary packaging and heat sealing of pallets are involved. Personnel protection is the highest priority here and is generally provided via guards. In the event of maintenance or malfunction, it must be possible to put the machine back into operation quickly and safely, in order to minimise unproductive downtimes.

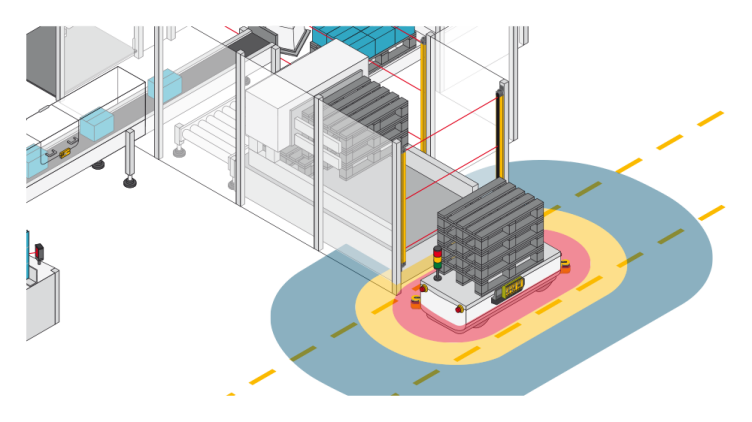

Whether it's access guarding and interlocking of safety gates, safe restart interlock in a robot cell, diagnostics and visualisation tasks for rapid troubleshooting or safe transport of packaging materials via automated guided vehicles (AGV) and vehicle systems (AGVS) – we offer the appropriate automation solution for end-of-line packaging.