As part of a retrofit, the production furnace manufacturer Aksoylar Robotik pursued its aim of converting its roller hearth furnaces to the state of the art in terms of operability, monitoring and safety. With the burner management system that was installed previously it was not possible to network the control units of the individual furnaces. What’s more, status, process and diagnostic data could not be displayed consistently, as desired, nor could error messages be assigned and rectified quickly.

With the safe small controller PNOZmulti 2, which has been adapted to the special needs of heat treatment furnaces, customers of Aksoylar Robotik can now safely monitor and simultaneously control multiple burners, plus the whole furnace, in one system.

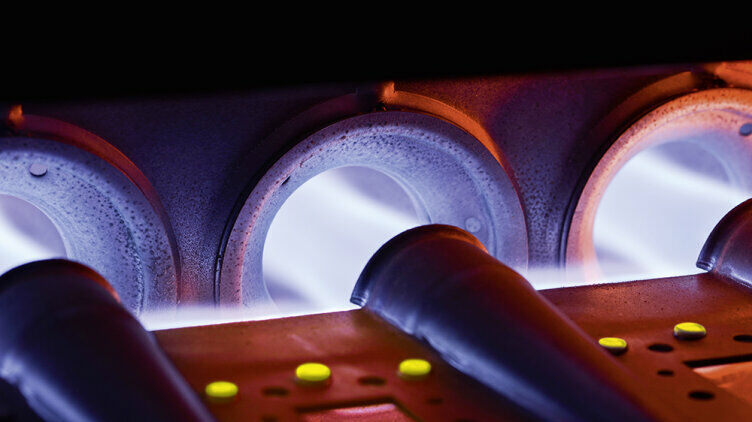

All fired up for safety

Efficient burner management for heat treatment furnaces

Supreme multitasking: the burner among controllers

The roller hearth furnaces from Aksoylar are equipped with multiple burners and are used for the specific heat treatment of metals such as steel and aluminium. They are flexible and intended for use in a variety of industrial applications. With safe monitoring of individual burners and simultaneous control of the entire furnace via the burner solution – in other words via a single safety system – for Aksoylar Robotik, it was the solution of choice. Using the software function block on the small controller, which electronically emulates the extended functionality of an automatic burner control, specific burner applications can be configured easily. For example, typical requirements include the control of safety, ignition and exhaust valves or the monitoring of combustion air pressure, flame, ignition and much more. The result: safe operation of burners, stable processes and, above all, high-quality production results in the roller hearth furnace.

Benefits at a glance

- Economical solution: all burners are controlled with a single centralised safety controller

- Centrally managed communication support for full control of processes, status and diagnostics

- Wide range of burner solutions for additional, new application options for user customers

Customer statement

“PNOZmulti 2 m B1 Burner was our favourite because we can use it to guarantee safe operation of the combustion process. The fact that our customers can use this solution to control all their burners in one system clearly makes it more economical, user-friendly and adaptable compared with all the previous versions they have installed.”

About Aksoylar Robotik Sistemler ve Makina

Aksoylar Robotik Sistemler ve Makina was founded in 1988, with its headquarters in Istanbul. It makes automated production furnaces, incinerators, combustion welding and induction welding machines and ceramic furnaces for broad swaths of the industry. The family business is now managed by the second generation, today employing 220 staff in planning, design and implementation. Aksoylar focuses on innovative, efficient and safe solutions for all technical requirements of industrial plants.

Our products in the application

Pilz South East Asia Pte. Ltd.

25 International Business Park, #04-56 German Centre

Singapore 609916

Singapore

Telephone: +65 6839 292-0

E-Mail: sales@pilz.sg

Telephone: +65 6829 2920

E-Mail: techsupport-sg@pilz.com