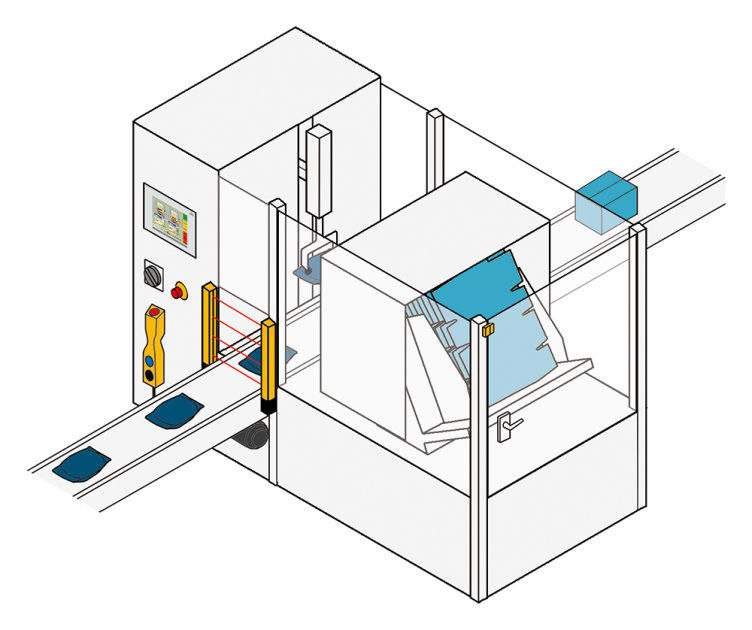

The configurable safe small controllers PNOZmulti 2 are used in virtually every area of plant and mechanical engineering. PNOZmulti 2 can be used to monitor safety functions safely and to perform standard control functions economically.

The configurable safe small controllers PNOZmulti 2 have a modular design: Select a base unit and then choose the required number of expansion modules to meet the needs of your application.

The compact standalone base unit PNOZ m C0 is not modular and expandable. With a 22.5 mm width, it's as narrow as a safety relay, but as powerful as a safety controller.

Both the hardware and the application configuration are created in the software tool PNOZmulti Configurator. Once completed, the configuration is loaded on to a program memory and inserted into the base unit. The configuration can be simulated offline prior to commissioning - no need for hardware.