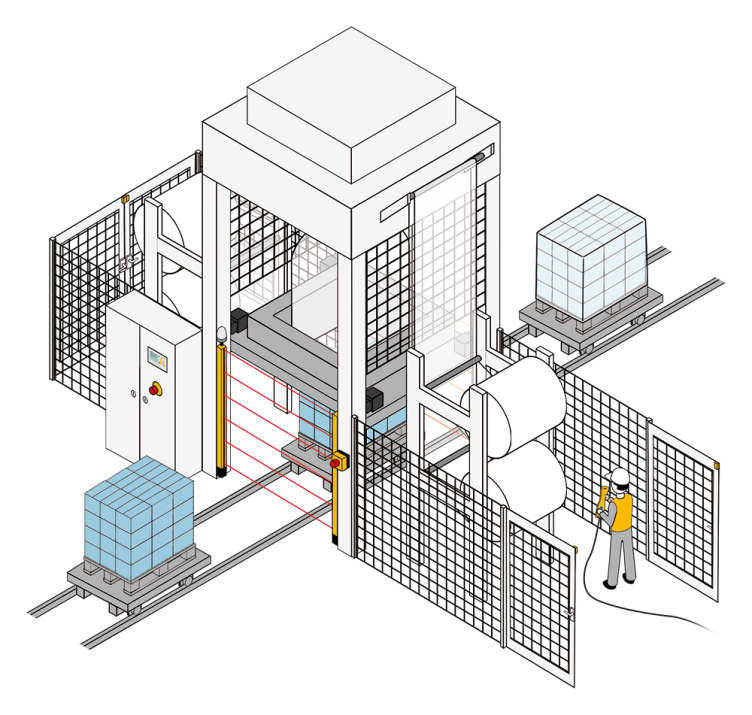

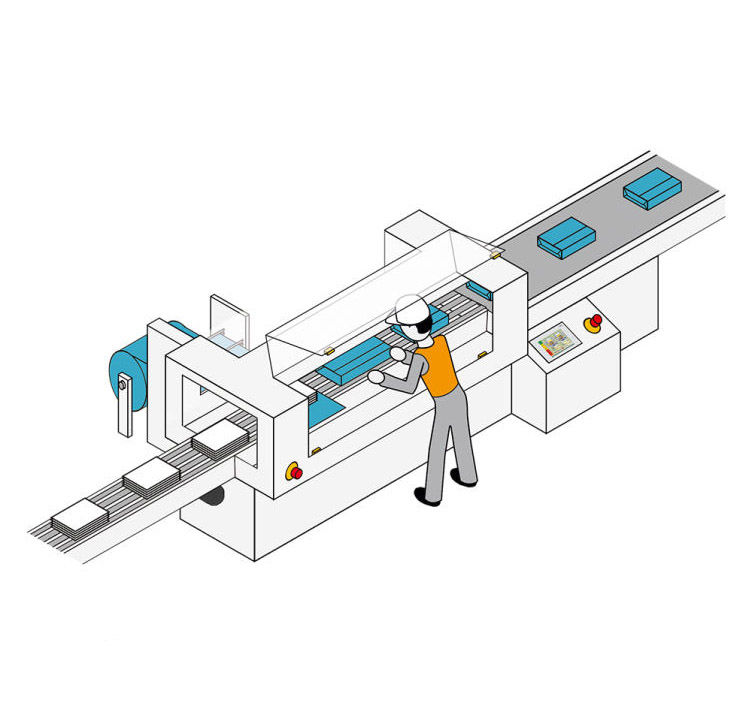

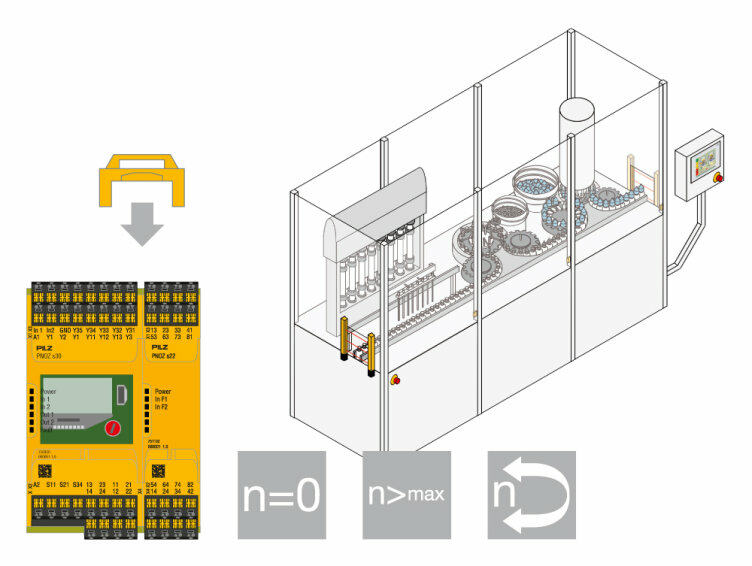

Using the speed monitor PNOZ s30, you comply with the Machinery Directive with respect to the requirement in drive monitoring to safely monitor and maintain the operating status of the drive when the drive is shut down, thus protecting the operators.

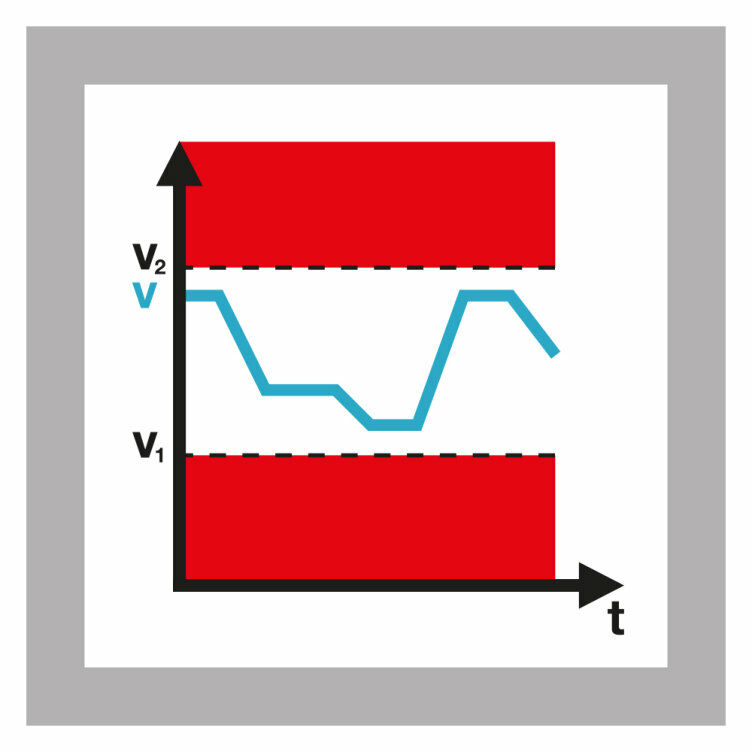

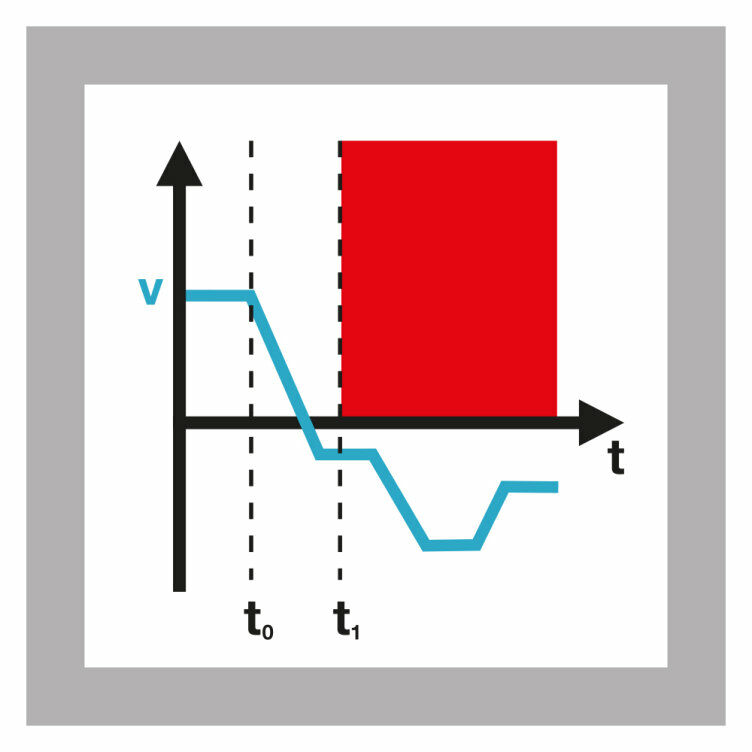

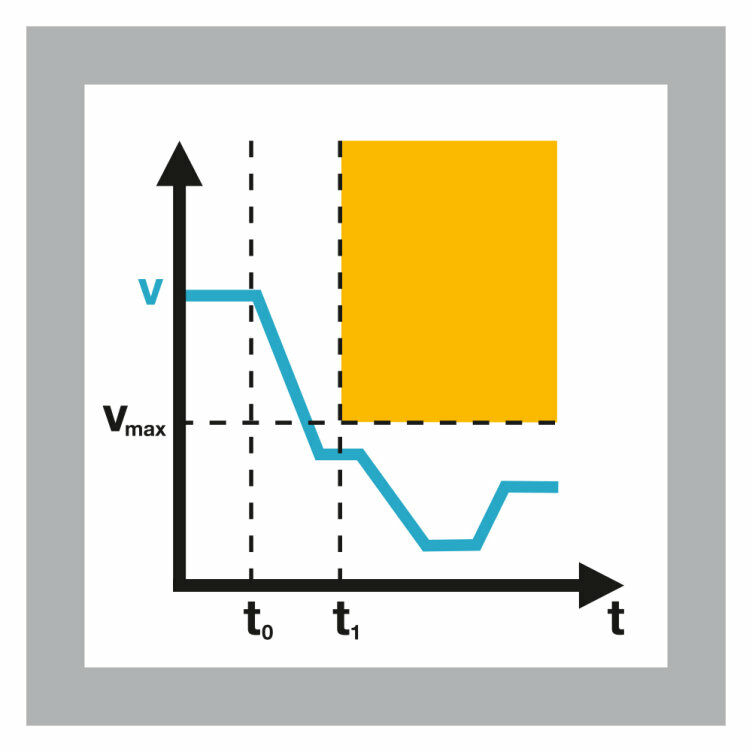

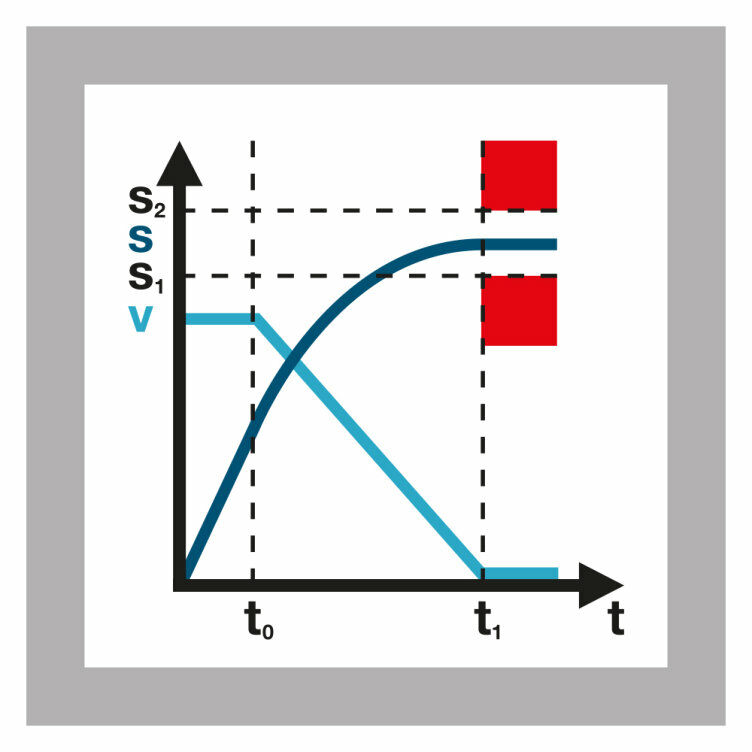

The speed monitor PNOZ s30 can be used in a wide range of applications and for monitoring a variety of functions. The user-friendly configuration is performed directly on the device or alternatively using the PNOZsigma Configurator. Typical applications for speed monitoring are balancing machines, high rack storage systems, centrifuges, filling systems, wind turbines or amusement parks. The safety functions that can be monitored in accordance with EN 61800-5-2 are listed below.