A safety light barrier is electrosensitive protective equipment (ESPE) and is categorised as a guard. It is used in industrial work environments, to guarantee the protection of employees and machinery. It is an effective safety device and operates in accordance with the principle of optoelectronic detection. This means that it uses light signals to monitor the status of the detection field.

Safety light barriers

What is a safety light barrier?

What is the purpose of a safety light barrier?

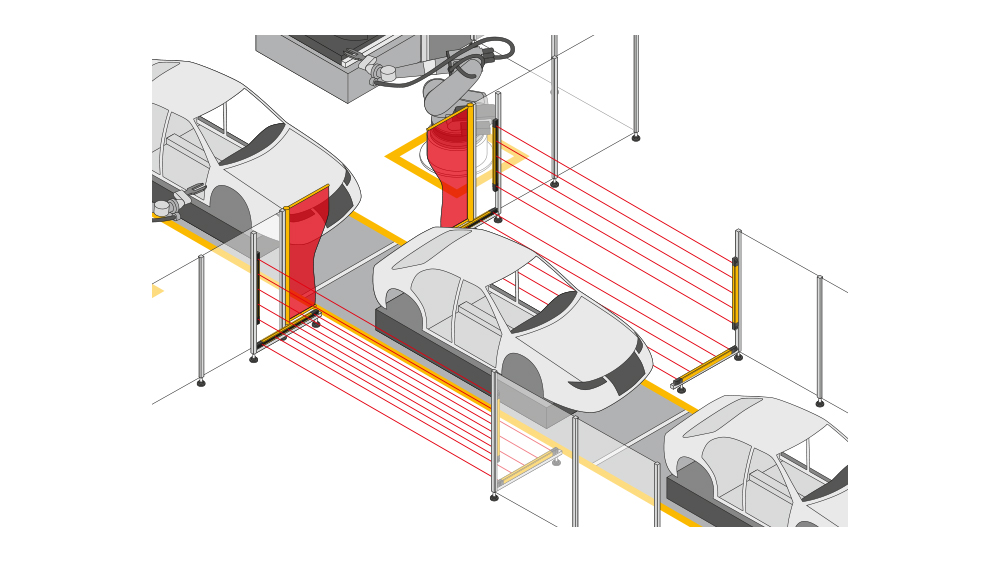

Safety light barriers are designed to satisfy high safety standards and to guarantee the protection of people and equipment. For example, they are used to safeguard danger zones via:

- Entry protection: A safety light barrier can be used to safeguard entry to particular areas or danger zones

- Access protection: A safety light barrier can be used to safeguard access to moving parts or machinery and protect people from injury. In industrial environments, safety light barriers are often used to safeguard areas containing rotating or moving machine parts, which might pose a risk.

The safety of the work environment is increased and the risk of accidents minimised due to the use of safety light barriers.

What is the difference between safety light barriers and simple light barriers?

Non-safety-related light barriers are mainly used to detect objects or to implement basic functions in industrial applications. They are used in various applications such as factory automation or the packaging industry.

In contrast, safety light barriers are intended to protect persons and meet certain safety standards. They are used in safety-critical applications in order to protect persons, objects or also machine processes.

What are the functions of a safety light barrier?

A safety light barrier offers a variety of functions in order to guarantee a safe work environment, for example

- Particularly robust to environment interference such as external light, vibration or contamination

- Fast reaction time, in order to detect hazardous situations

- Integration with existing safety systems

- Absence of dead zones – many light beams monitor up to the edge of the housing

- They often have a coding option, so that light curtains do not interfere with each other

What types of safety light barrier are there? What are the application scenarios?

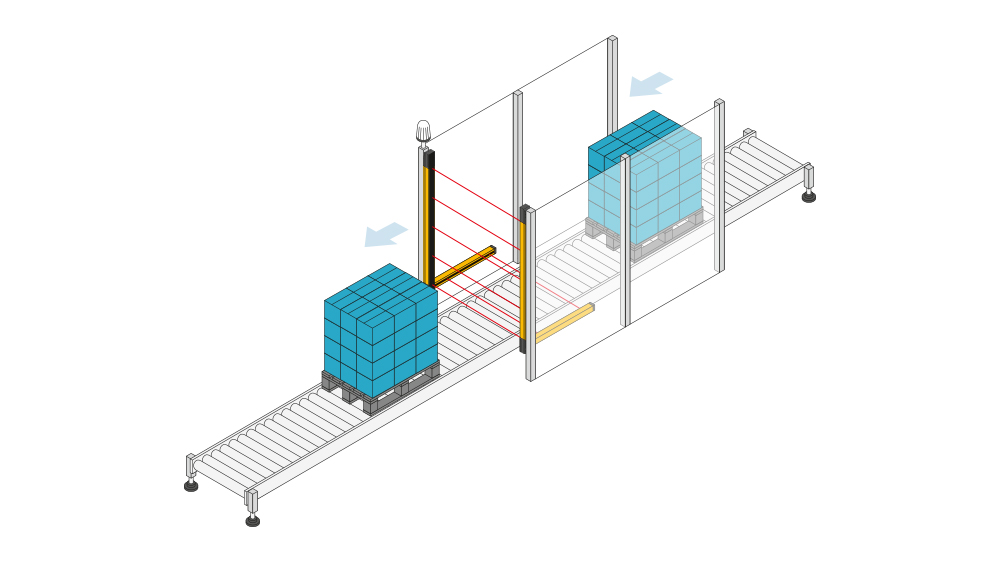

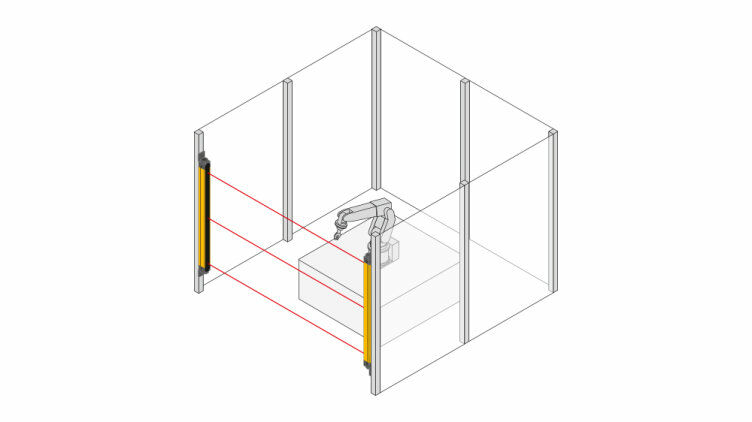

Single-beam safety light barriers have only one light beam and are suitable for smaller areas. Multi-beam safety light barriers have multiple light beams (generally two to four) and can also cover larger areas. They are also called body protection light barriers.

With multi-beam safety light barriers, a distinction is made between safety light grids and safety light curtains: The difference lies in the resolution of the beam field. This is finest on the safety light curtain.

Single-beam safety light barriers

Monitoring of smaller areas such as access points to particular areas, e.g. machine entrances or areas around gates

Multi-beam safety light barriers

Monitoring of larger areas such as conveyors or large machines. Use for body protection.

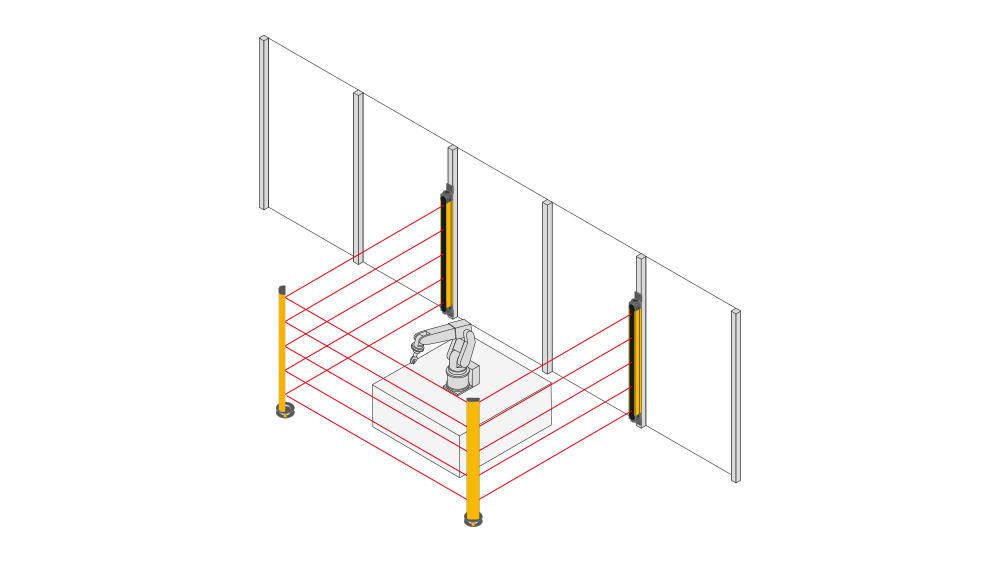

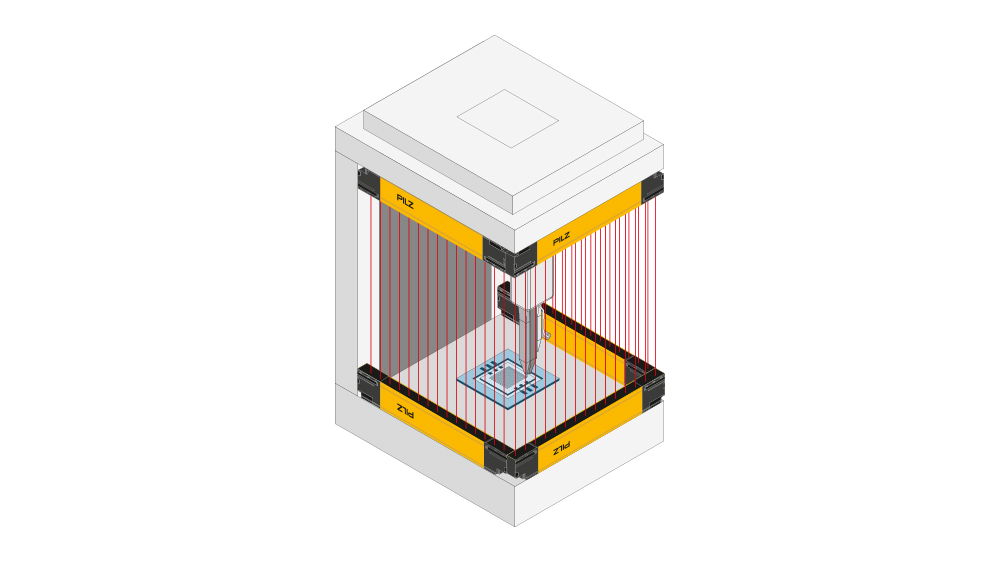

Safety light curtains

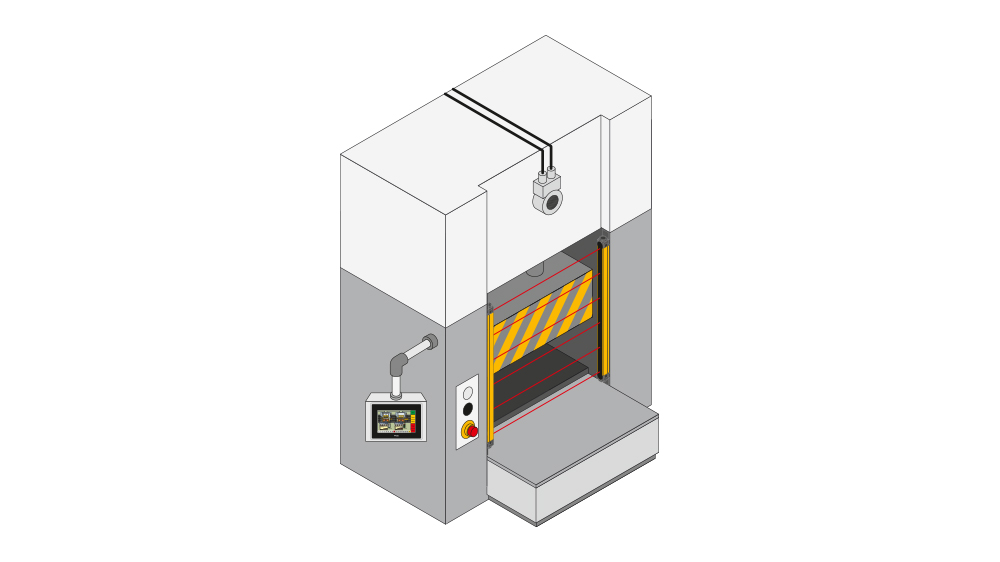

Monitoring of larger areas such as protection of areas around robot cells or hazardous machines. Use for hand protection.

Safety light curtains

Non-contact safeguarding of danger zones on presses, shears or moving machine parts. Use for finger protection.

In which areas is a safety light barrier used?

Safety light barriers are used in a variety of areas, particularly where reliable monitoring and safeguarding of danger zones is required.

Further information

Pilz New Zealand

4 Prescott Street, Penrose

Auckland 1061

New Zealand

Telephone: +64 9 6345350

E-Mail: office@pilz.co.nz

Telephone: +64 9 6345350

E-Mail: office@pilz.co.nz