Opt for Pilz electronic monitoring relays! Whether for monitoring voltage, phase sequence, current, insulation, true power, temperature, standstill or fault voltage, you will find the right device for every monitoring task. Reliable electronic monitoring and control of your machine or system is always the priority.

Electronic monitoring relays PMDsrange

Taking control of every situation

Advantages of using the monitoring relays PMDsrange

- Parameters can be set on the front, meaning short commissioning times

- Saves space in the control cabinet: Widths of just 22.5 mm

- Rapid diagnostics via LED status display

User-friendly features

- Thermistor monitoring relays have ATEX certification

- Dimensions (H x W x D): 87 x 22.5 x 122 mm

- Selectable measuring ranges

- Available in all operating voltages

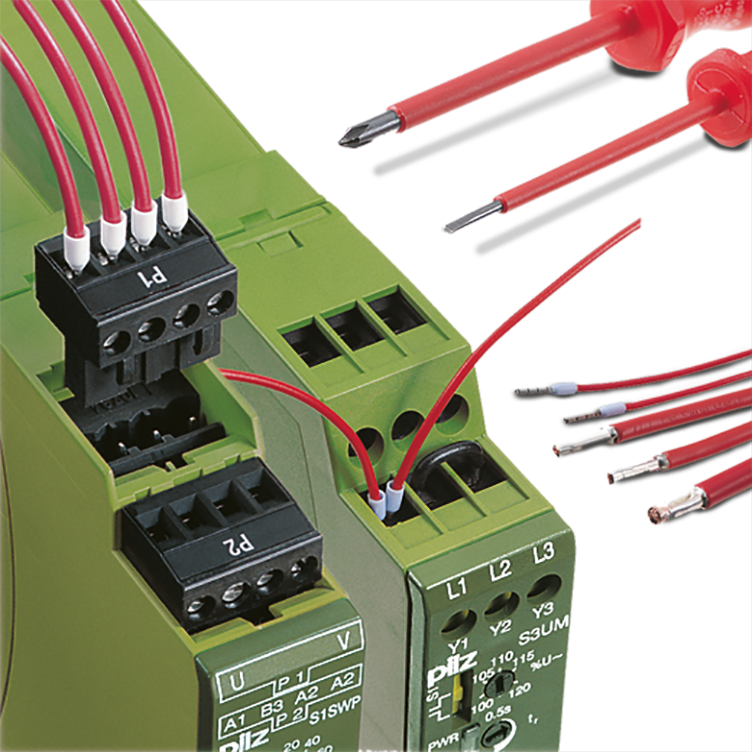

Operation – Purely a matter of setting: PMDsrange monitoring relays can be set to the required range and operating mode with the aid of a screwdriver. Tool-free snapping onto a mounting rail guarantees quick and easy installation.

Save space in the control cabinet: The compact, slimline casing of the monitoring relay has an installed width of 22.5 mm. Together with its high performance and functional density, it occupies only minimal space in the control cabinet.

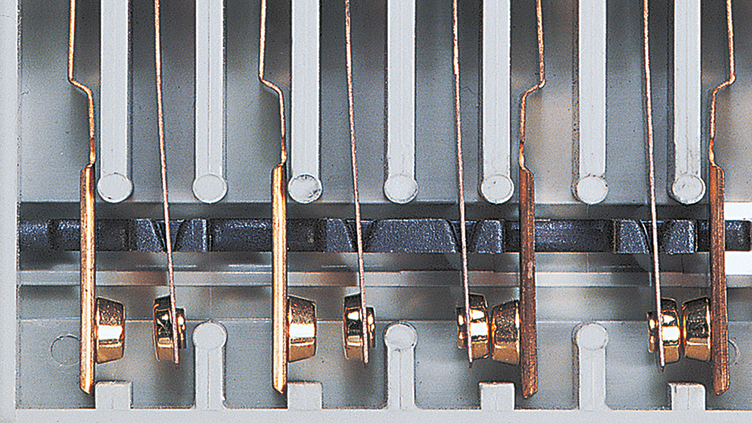

Contacts – Lifelong strength: Contacts on all monitoring relays are designed for an amperage of 100 mA to 5 A. Some monitoring devices have relays with special contacts, enabling them to switch smaller currents safely, right down to 1 mA.

Terminals: Our terminals are designed for cable cross sections from 0.25 mm up to a max. of 4 mm. Up to 2 cables (max. 1.5 mm per cable) may be attached to one terminal.

LED displays: All monitoring relays have two highly luminous LEDs, one green indicator for operating voltage and one red fault/status indicator.

Electronic monitoring relays in practice

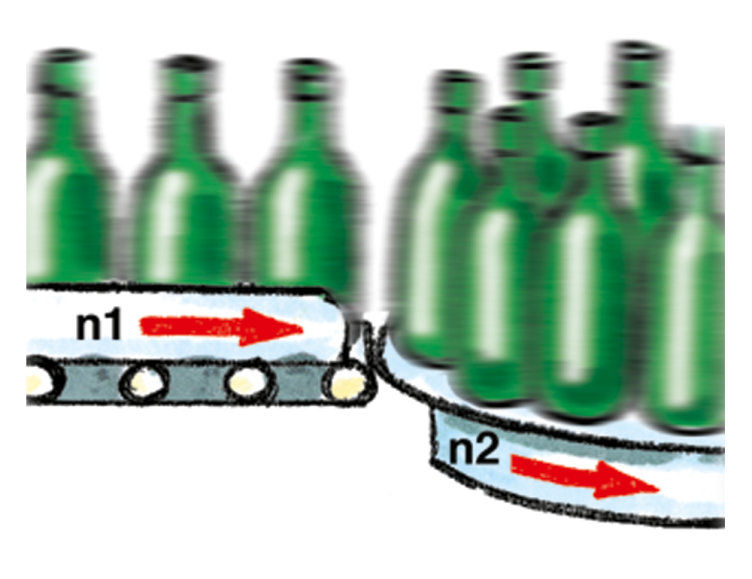

"Bottling plant" with voltage monitoring

Use voltage monitors, for example, to monitor voltage supplies on bottling plants. The monitoring relay ensures that the plant is shut down in a controlled manner. It also protects against an uncontrolled restart.

"Rollers" with phase sequence monitoring

Use phase sequence monitors to monitor the phase sequence. This will reduce the number of hazardous situations for man and machine. On rollers on which the direction of rotation has been set incorrectly, for example.

"Hospital" with insulation monitoring

Use insulation monitoring in hospitals. These enable you to achieve higher availability e.g. in operating theatres thanks to preventive maintenance and advance information.

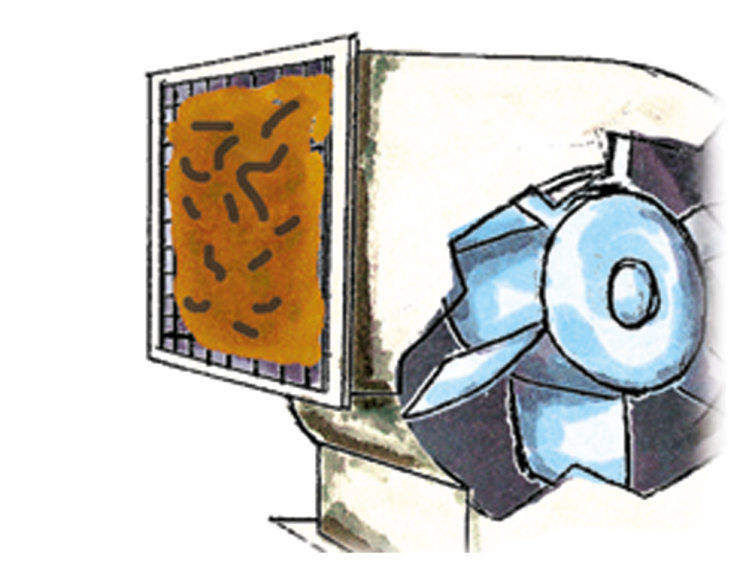

"Air conditioning plant" with true power monitoring

The range of different true power monitors is as diverse as the number of applications. Using the measured true power, it is possible to derive variables such as fill level, volume, torque or air pressure, for example. So it is possible to check contamination, flow rate or wear and tear on an air conditioning plant.

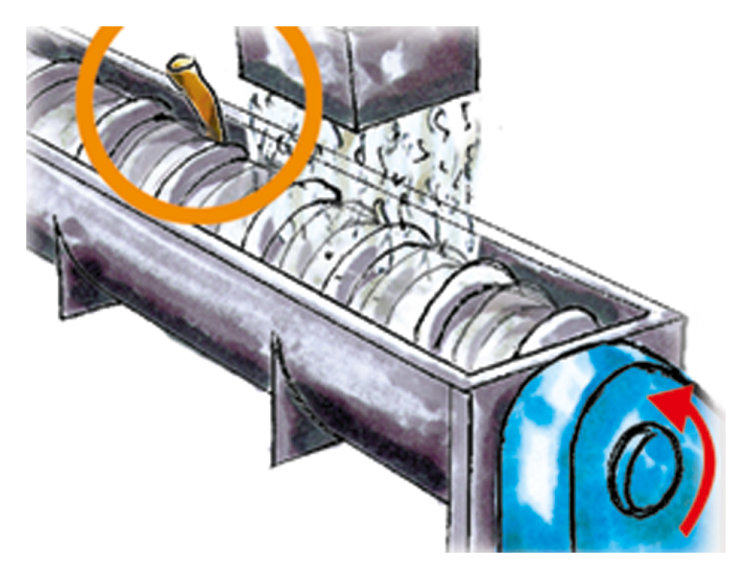

"Screw conveyor" with current monitoring

You need to monitor current, e.g. at a screw conveyor? It can provide protection against blockage and wear and tear, thereby helping with preventive maintenance.

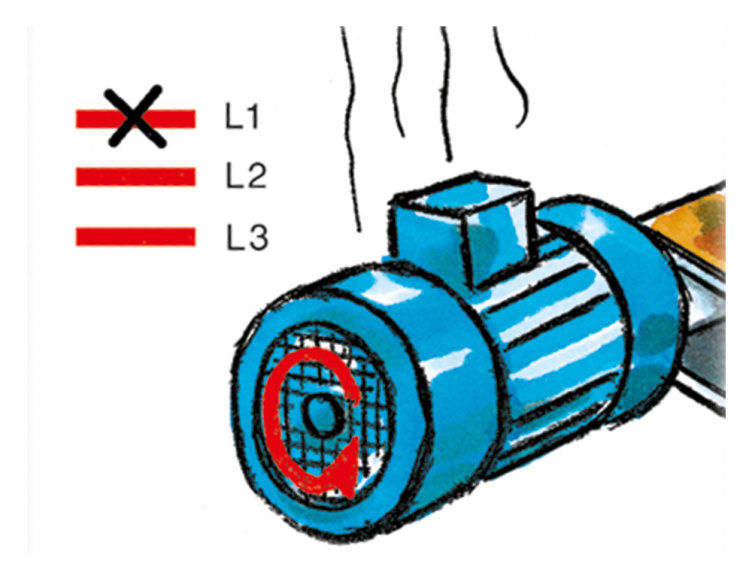

"Motor" with thermistor monitoring

Use thermistor monitoringto protect your motors from overheating. Also prevent automatic start-up. This is particularly important for adverse cooling and where frequent start-up or braking of the motor is required.

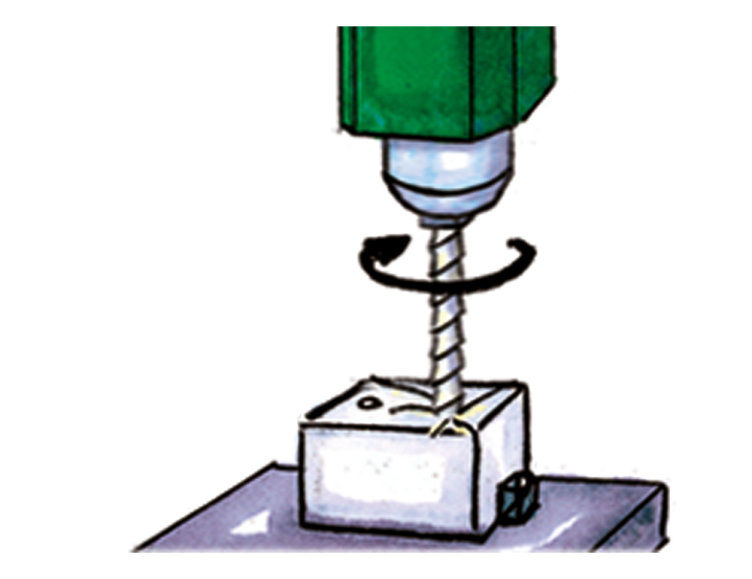

Automatic tool change on a drilling machine" with standstill monitoring

Initiate automatic tool change as soon as standstill is achieved! It's possible thanks to standstill monitoring. Where you have tools with different run down times, it is possible to resume work more quickly. So you can improve your cycle times. Without standstill detection, automatic tool change would be calculated to suit the tool requiring the longest run-down time.

“Monitoring fault voltage and insulation on welding transformers”

According to VDE 0545, welding transformers, e.g. in automotive body shops, are monitored for hazardous contact voltages and insulation defects. You can monitor up to six secondary windings on welding transformers independently for hazardous voltages. You can also detect shorts across contacts and earth faults. At the same time, you can monitor and display the correct earth connections.

Of course, you can also use the monitoring relays PMDsrange for applications other than those described here.

Our product range: PMDsrange

Pilz New Zealand

4 Prescott Street, Penrose

Auckland 1061

New Zealand

Telephone: +64 9 6345350

E-Mail: office@pilz.co.nz

4 Prescott Street, Penrose

Auckland 1061

New Zealand

Telephone: +64 9 6345350

E-Mail: office@pilz.co.nz

Telephone: +64 9 6345350

E-Mail: office@pilz.co.nz