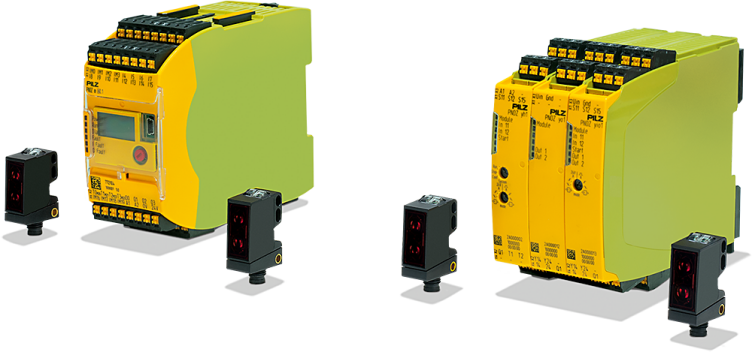

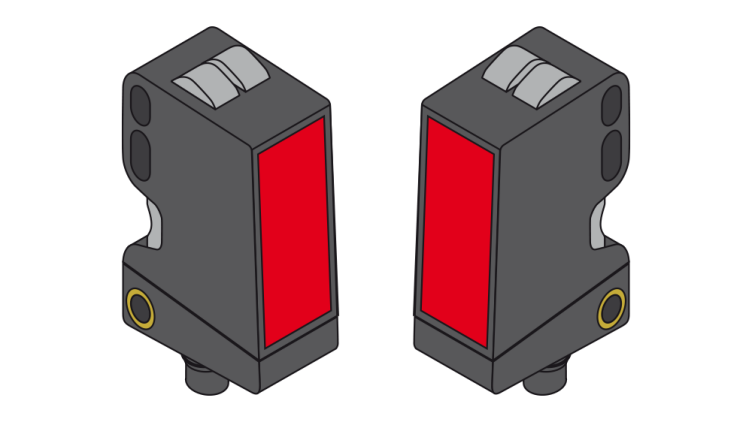

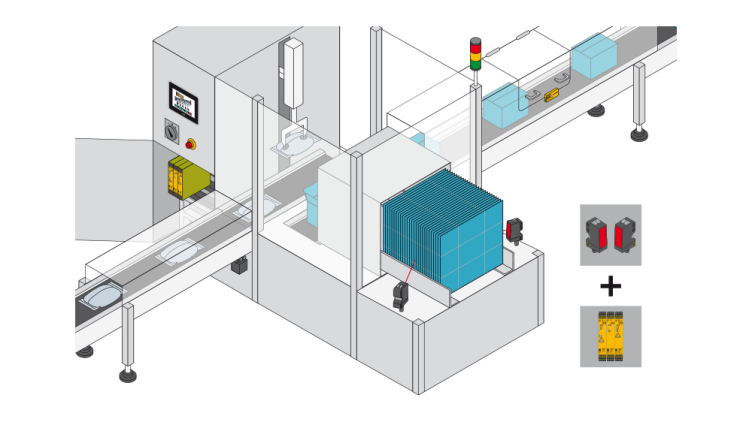

Photoelectric proximity sensors detect an object by emitting light beams, which are reflected by the material. In this way, reliable object detection can also be guaranteed for shiny or reflective objects. The sensors do not fulfil a safety function. However, they do emit a switching signal, which is evaluated by safe control technology from Pilz, such as the small controller PNOZmulti 2 or the modular safety relay myPNOZ.

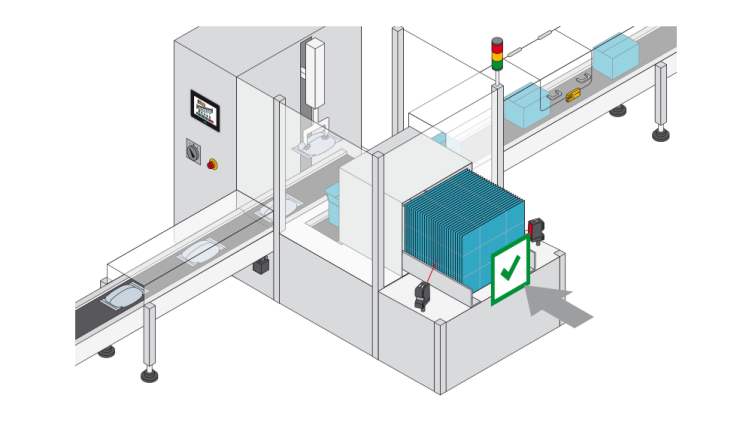

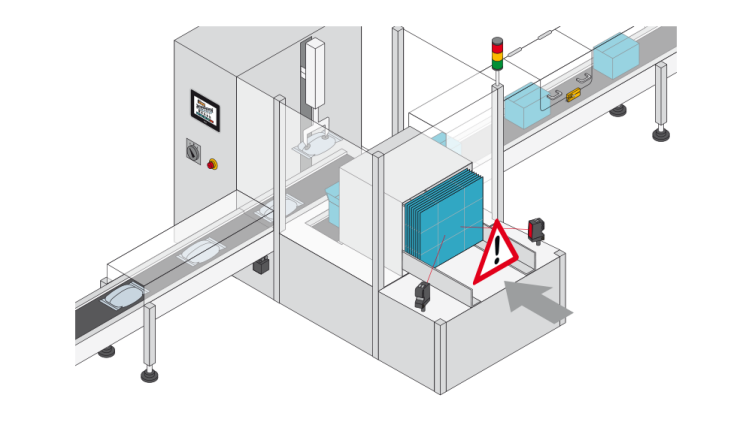

For example, photoelectric proximity sensors are used in solutions for packaging machines for safe monitoring of cardboard feed. The solution is TÜV-SÜD-certified for PL d / SIL 2.