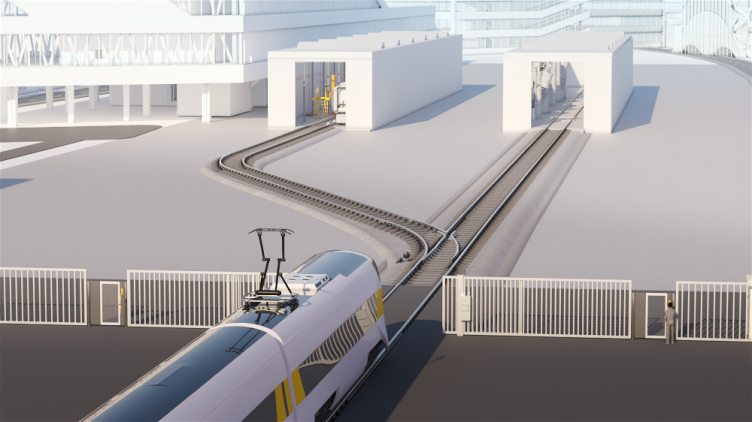

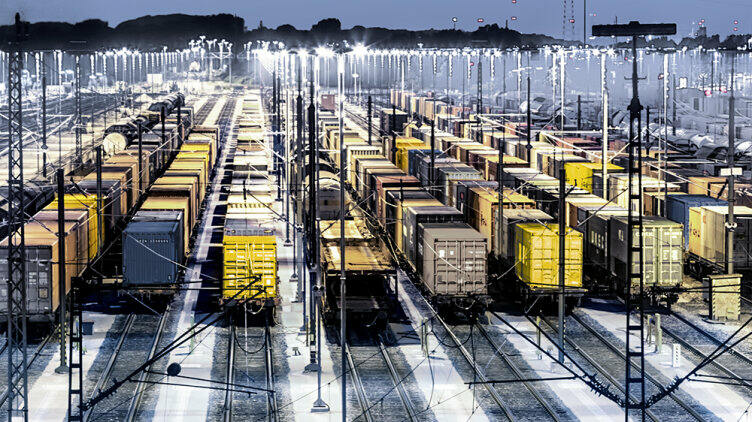

From hardware component to the complete safety concept: for you, we have extended our industrial expertise from the fields of machinery safety and health and safety regulations to railway premises. With our knowledge and experience, we demonstrate the same competence on railway premises as we do in an industrial environment.

We can provide support with the safety-related assessment and implementation of standard-compliant solutions for maintenance and repair, as well as washing plants and railway/tram cranes - that's for both passenger and freight traffic.