Automation technology helps manufacturing to be more economical and sparing on resources. Safe automation technology from Pilz supports our customers on the road to sustainable production. For a lower failure rate and increased availability and productivity. In short: for a long life for plant and machinery. That’s why Pilz has Industrial Security in its sights and provides support right through to a secure infrastructure in the production environment. Pilz offers its customers top-quality, energy-efficient and environmentally-friendly automation solutions – we always have the conservation of resources in our sights.

Sustainable automation

Product quality

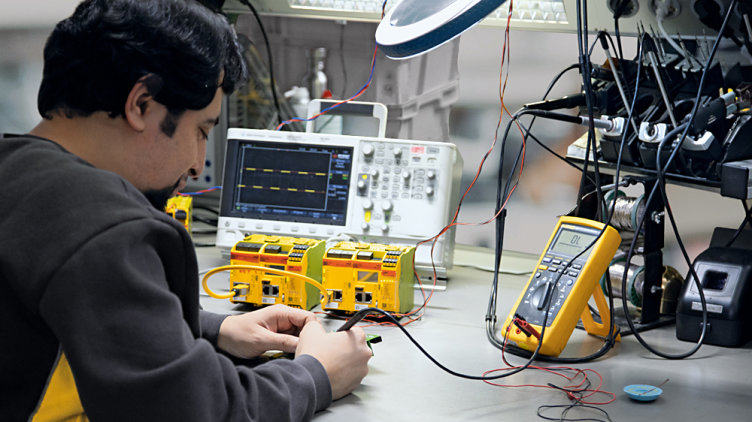

Quality is our product promise. Fewer returns mean that materials are not wasted. However, should a device be defective, we invite customers to return it to us. Our employees can then check the extent to which the defective device can be re-used, either by repair or by exchanging individual components.

Return and disposal

Within the framework of the changes to the Electrical and Electronic Equipment Act (ElektroG) in 2021, we offer our customers in Germany the option to return our products at the end of their lifecycle. The WEEE Directive 2012/19/EU (Waste of Electrical and Electronic Equipment) was adopted back in 2012. Among other things, this European directive deals with the labelling and return of electrical and electronic equipment via the manufacturer. The devices are disposed of or recycled professionally. Our international subsidiaries are registered locally and offer their customers a disposal solution. What’s more, we are continuously working on reducing pollutants in our products.

Further recycling measures:

- Waste products are recycled

- The recycling is prepared by separating the waste in our buildings.

- Packaging made of 100% recycled paper

- Film waste is minimised

Through these measures we have already been able to increase the waste recycling rate to 95%!

Energy efficiency

Our aim is to develop environmentally-friendly products by using ecological materials and energy-saving technologies. The development department puts energy efficiency as a requirement of new products and technological advances, right at the start of the product lifecycle. In line with our corporate goals, each of our product generations is more efficient than its predecessor. This applies to all controllers, relays and sensors, as well as functions relating to actuator technology.

Three product examples:

Retrofit with all-round sustainability

With a retrofit, “old” plant and machinery that no longer meet today’s safety standards is upgraded by Pilz to the state of the art. As a result, it can continue to be operated safely and efficiently, without whole plants having to be scrapped and new ones purchased. In this way, Pilz supports its customers worldwide in their quest for sustainability, resource conservation and waste reduction.

As automation experts, Pilz supports the whole retrofit process:

- Hazard assessment

- Safety concept

- Safety design

- Selection of suitable safety components

- System implementation

- Verification

- Validation

- Technical documentation

- Employee training

- Where necessary: renewed CE marking

Further information

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern

Germany

Telephone: +49 711 3409-0

E-Mail: pilz.gmbh@pilz.de

Telephone: Commercial : +33 3 88 10 40 01 - Commande : +33 3 88 10 40 02

E-Mail: devis@pilz-france.fr