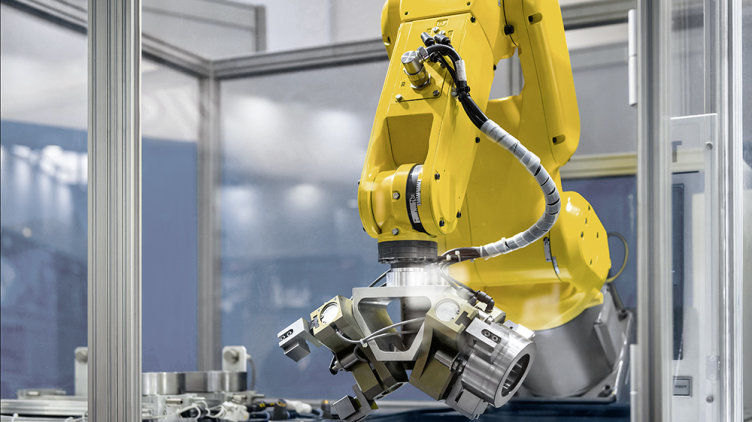

As a member of the demonstration and research platform SmartFactoryKL we are actively involved in formulating uniform standards for Industrie 4.0. The platform's goal is to test innovative factory systems, in which the vision of Industrie 4.0 becomes a reality.

We are working jointly with the other partners of SmartFactoryKL on a production line that demonstrates the practical application of the central aspects of Industrie 4.0. A storage module by Pilz is used to provide intelligent, automated storage for the workpiece carriers. It uses control systems, various sensors, drive technology, network infrastructure components and operation and visualisation systems from Pilz.