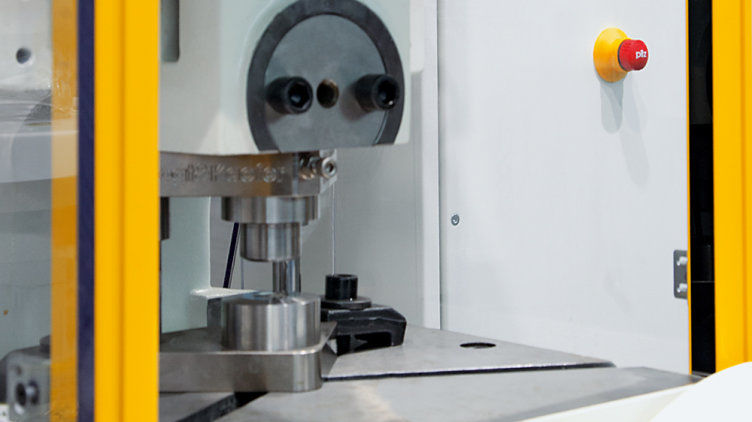

Reliable safety technology for presses should not only be flexible and powerful, but economical too. We can help you to equip and retrofit your presses safely and guarantee safe operation. As an experienced partner in forming technology, Pilz can guide you through a new design and retrofit over the entire machine lifecycle, to guarantee press safety.

Presses

Safety-related equipment, upgrade and operation of presses

New standard series EN ISO 16092 for press safety!

The standard series EN ISO 16092 consists of four parts. Part 1 describes the safety aspects common to all presses. Part 2 deals with mechanical presses, Part 3 with hydraulic presses and Part 4 with pneumatic presses. In accordance with the Machinery Directive, presses are subject in part to Annex IV. In other words, they are included among the ”hazardous machinery” with a special conformity procedure, which is based particularly on harmonised EN standards. EN ISO 16092 Part 1 and Part 3 have been harmonised since March 2019. The transition period ends in September 2021 for EN 692 and EN 13736 and in March 2021 for EN 693.

- EN ISO 16092-1: Machine tools safety - Presses - Part 1: General safety requirements

- prEN ISO 16092-2: Machine tools - Safety of presses - Part 2: Mechanical presses. Predecessor: EN 692

- EN ISO 16092-3: Machine tools safety - Presses - Part 3: Safety requirements for hydraulic presses. Predecessor: EN 693

- prEN ISO 16092-4 Machine tools - Safety of presses - Part 4: Pneumatic presses. Predecessor EN 13736.

Key changes

- The level of the individual safety functions were still defined in accordance with EN 954-1, which was withdrawn some time ago. The current standard series now contains the requirements with the required performance level in accordance with EN ISO 13849-1.

- The drive type for initiation of hazardous movements has been completely revised and reassessed with regard to accessibility.

- The specifications for noise measurement have been revised.

- The standard series was published with a general part, independent of the drive type, and parts of the standard that are press-specific.

What does Pilz have to offer in the field of press safety?

- More than 25 years’ experience in press safety

- Member of the European mirror committee for DIN, with direct access to the respective current standard position

- Safety solutions for all types of press: with our services from risk assessment to international compliance

- Implementation of complex technical assessments and measures on the respective machinery

- Press retrofit as well as new machine business

- Implementation of complete press controllers: for new presses as well as renovations of existing plants

- Products: the safe small controllers PNOZmulti 2 and the automation system PSS 4000 with special modules and software blocks for the safe control of presses.

Safe presses – with the configurable small controllers PNOZmulti 2

PNOZmulti 2 are modular safety controllers: there are two base units and numerous expansion modules available for various application options. Application of the small controllers is particularly user-friendly with the freely configurable software tool. You can configure both the hardware and the necessary software functions directly in the tool.

We have developed the dual-pole semiconductor output module PNOZ m EF 8DI2DOT to monitor mechanical presses. It is used to actuate press safety valves, as well as other actuators that require dual-pole switching. PNOZ m EF 8DI2DOT has two safety outputs and eight digital inputs, for which a filter time can be configured. Benefit from short cycle times of approx. 3 ms and fast reaction times of under 8 ms. Press safety functions are quick and easy to configure with certified press blocks in the PNOZmulti Configurator!

Whether it’s a new press or a press retrofit: with a width of 22.5 mm, the new press module will fit in any control cabinet!

Safety solutions and concepts for all types of press

From a manually operated standalone workstation to a fully automated press line, we can provide solutions for all types of press. For special requirements in press technology Pilz has developed an electronic rotary cam arrangement, which increases both the productivity and safety of the press in combination with the automation system PSS 4000. For press brakes in particular we can offer an extremely productive solution with the camera-based protection and measuring system PSENvip.

Retrofit – Extend the productivity of older presses

When press retrofits are planned and implemented on a sound basis, our experts can equip even older models with the latest electrical, control and safety technology. For example, eccentric or hydraulic presses are characterised by a long service life thanks to their solid base and robust mechanics. Following a retrofit, they can go on to meet press safety, productivity and quality requirements for a further 10 to 20 years.

Benefits for press safety

Our solution for press safety

- Safety for human and machine while maintaining high availability and flexibility

- Higher productivity through optimised work practices and the very latest control and sensor technology

- Reduced standstill and downtimes

- Services to cover the entire machine lifecycle: from risk assessment to CE certification through to specific user training

- Approved safety concepts in accordance with international norms and standards.

Find out more about Safety solutions and concepts for your machine tools.

Downloads

Read our flyers for further information on our press and metalworking services. There you can discover what we have to offer in terms of press equipment, retrofit and operation.

Flyer to download: "Safety-related equipment, upgrade and operation of presses"

Still have questions? Just contact us!

Pilz South East Asia (Thailand) Co., Ltd

3 Lat Phrao Soi 3, Chom Phon, Chatuchak, #12th Floor, Promphun Building 3, 1201 - 1202

Bangkok 10900

Thailand

Telephone: +66 2105 4613

E-Mail: salesthailand@pilz.com

Telephone: +66 210 54613

E-Mail: techsupport-sg@pilz.com