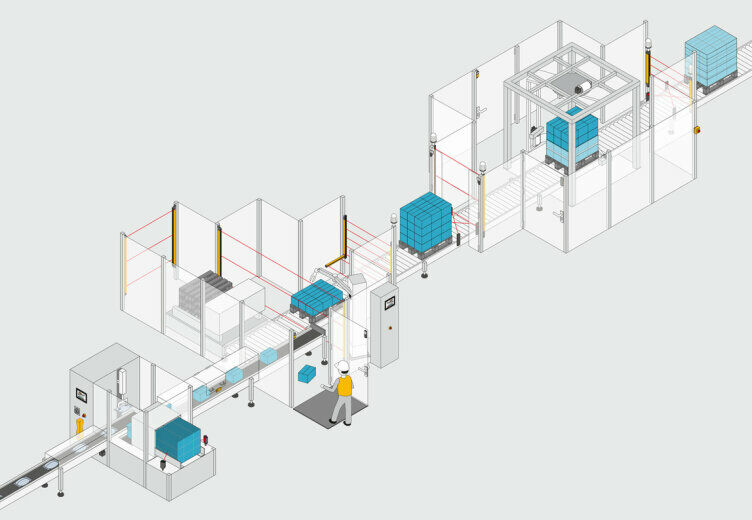

Efficient packaging processes require a high level of automation in the packaging industry. At the same time, the Machinery Directive lays down essential requirements of the functional safety of packaging automation. Particularly with packaging automation in primary packaging, a so-called critical infrastructure, there are very high requirements for the robustness of the products used and protection against manipulation. The packaging lines are subjected to a wide range of cleaning processes and strict quality inspections. The traceability of manufacturing processes is just as important as the access and permission management of individual employees and data protection.

Safe packaging automation

Flexible solutions for Safety and Security in packaging automation

Our packaging automation solutions - in each phase

Let's WRAP this up together

We support manufacturers and operators of packaging machines with the implementation of their packaging automation. As a renowned and reliable supplier of machinery safety services, we are there for both domestic and international companies.

Rely on future-proof, intelligent technologies and solutions for Safety and Security and benefit from the comprehensive services portfolio, ranging from risk assessment to full engineering. Based on more than 30 years of industry experience, we offer practical answers to both general and industry-specific questions relating to safety.

Our services portfolio identifies your requirements and assesses the specific risks prevailing locally on the machine. We support the entire engineering process, undertake CE marking in accordance with the Machinery Directive 2006/42/EC and so create international legal certainty for your packaging plant and your staff.

Benefits to you

- Comprehensive product line and range of services for the packaging industry

- Holistic solutions for Safety and Security

- Individual consultation for needs-based solutions

- Expertise relating to international standards and directives thanks to many years of industry experience

- Risk analysis and safety concept for all your machinery

- Flexibility thanks to open interfaces and decentralised system architecture

- Time and cost savings with the help of simple configuration and programming software

Head to the digital showroom to discover our 3D packaging machine and learn even more about automation solutions in packaging technology.

Pilz podcast – listen in now!

Optimise overall equipment effectiveness through complete automation solutions

A key indicator for high productivity and efficiency in packaging technology is Overall Equipment Effectiveness (OEE). It determines the added value of a packaging line and can quickly demonstrate a plant's productivity at a glance. Safe automation solutions are the basis for optimum Overall Equipment Effectiveness. So not only does machinery safety provide protection against avoidable accidents, but it also contributes towards an economical, efficient packaging process (fewer downtimes, inclusion of capacity planning (Predictive Maintenance)).

Efficiency can also be improved with the new opportunities of Industrie 4.0. Guaranteeing safety for man and machine is a key issue in reducing the Total Cost of Ownership (TCO). An individual safety concept for your packaging machines is critical for optimised operation. Industrial Security - in particular the protection of sensitive end customer data in networked plants - plays an increasingly important role.

Further information on the packaging industry at Pilz

Pilz South East Asia (Thailand) Co., Ltd

3, Promphan 3 Building, Unit 1201 - 1202, 12th floor, Soi Lat Phrao 3, Lat Phrao Road, Chom Phon, Chatuchak

Bangkok 10900

Thailand

Telephone: +66 2105 4613

E-Mail: salesthailand@pilz.com

3, Promphan 3 Building, Unit 1201 - 1202, 12th floor, Soi Lat Phrao 3, Lat Phrao Road, Chom Phon, Chatuchak

Bangkok 10900

Thailand

Telephone: +66 2105 4613

E-Mail: salesthailand@pilz.com

Telephone: +66 210 54613

E-Mail: techsupport-sg@pilz.com