On machines with electrosensitive protective equipment (such as laser scanners or light curtains for example), safety is guaranteed by the distance between the hazardous movement and the electrosensitive protective equipment. Where there is intervention/access to the danger zone, no more rundown movements may occur!

Overrun is the time and/or distance needed by a hazardous movement in order to come to a standstill after a shutdown:

-

Total overrun time = Reaction time of the controller + stopping time of the mechanical system

Put simply, the overrun measurement is the metrological evidence that the necessary safety distance is maintained.

The result of an overrun measurement is a safety distance, which is stated in millimetres. Once the measurement has taken place, it is necessary to check that the distance between the electrosensitive protective equipment/scanner field dimensions and the hazardous movement corresponds to the measured result.

Why is an overrun measurement necessary?

For protective devices on machinery, such as light curtains, scanners or two-hand controllers, the Machinery Directive requires that persons cannot reach the moving parts while the parts are moving. This requirement is guaranteed by maintaining the safety distance between the hazardous movement and protective devices.

That's why the machine manufacturer must determine the overrun and use it to calculate the required safety distance. These results must be stated on the machine or, for example, in the operating manual. The methods described in EN ISO 13855 can be applied for this calculation.

One of the obligations of machine operators is to provide employees with safe machinery, so when safeguards are inspected, compliance with the safety distance must also be monitored. The safe function of all safety components and their incorporation into the controller, plus protection against tampering, must be tested prior to initial commissioning and, where appropriate, at defined, regular intervals. Common practice for such inspections is to repeat the inspection annually.

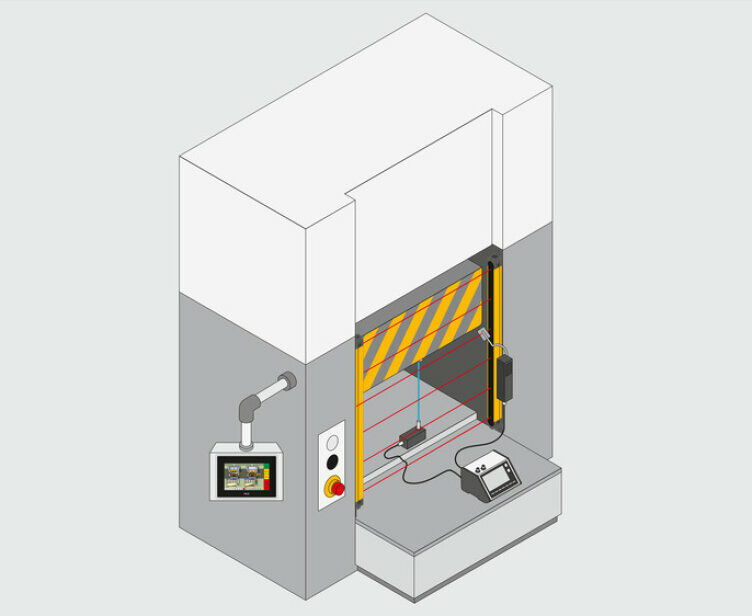

Procedure for overrun measurement

To carry out an overrun measurement you need a sensor (e.g. a wire-actuated encoder), the overrun measurement device itself and an actuator (e.g. a hand simulator). The hand simulator is mechanically fixed to the safeguard on the application/machine. The hand simulator interrupts the safeguard (e.g. light curtain) when the application is at its highest speed. Activating the safeguard triggers a machine stop. Using the wire, from this point, the overrun distance and the time it requires is calculated by considering the position and speed of the hazardous movement.

This process is repeated 10 times in succession. The worst value from these 10 repetitions specifies the minimum safety distance between the safeguard and the hazardous movement.

Regular inspection of safeguards

The inspection body that is part of Pilz GmbH & Co. KG, Ostfildern, undertakes the legally prescribed inspection of safeguards. Pilz operates an independent inspection body, accredited by DAkkS in accordance with ISO IEC 17020. Accreditation means that the technical competence, reliability, independence and integrity of the Pilz inspection body is assessed and regularly monitored in the public interest.

After the inspection, which includes among other things the overrun measurement, you'll receive a detailed inspection report. If the inspection is passed, the machine is also given a Pilz seal.