The Canadian Bombardier group builds trains in the Belgian city of Bruges. Before the trains can be incorporated into the international rail network there are some functional and electrical tests they need to pass. In high-voltage test cages, Bombardier tests more than 5,000 connection points per train under 1,000 Volt high voltage. Pilz is responsible for development and implementation of the necessary safety concept.

Stress-free test conditions for new trains

Safe high-voltage test mode

For the technical development of the test cages Bombardier works with SPIE, a technical service provider for buildings, plants and infrastructures. While SPIE implemented the plant’s mechanics and electronics, the partners turned to Pilz's expertise with regard to safety issues: Pilz carried out all the calculations, programming, validation and concept development. Safe, functioning operation of the test facility is the result.

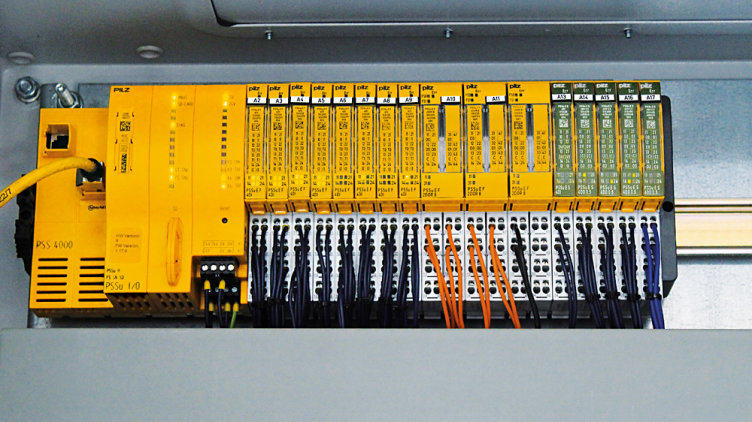

In detail, the automation system PSS 4000 controls not only the emergency stop and the coded safety switch PSENcode but also all the safety-related inputs and outputs. PSENcode monitors the doors to the test cage to prevent unauthorised opening. What''s more, as soon as an emergency stop is triggered, power is removed from the entire cage. Staff at the control panel can perform rapid diagnostics for these safety functions. The result is an efficient test operation with low plant downtimes.

The benefits at a glance:

- Holistic safety concept from risk assessment to operation with the automation system PSS 4000

- Test managers can stop processes themselves, to carry out checks and prevent unsafe situations

- Less programming work: simply add extra objects to an application program in the automation system PSS 4000

"The aim of this project is to ensure that technical development of the test cages is going in the right direction. Our speciality lies in implementing the mechanical and electrical aspects of the plant; for safety issues we have relied upon the expertise of Pilz.”

“Safety is a continuous process, in which we will keep investing. We are delighted that Pilz can help us with this. We will happily count on Pilz again in future projects and when changes are required.”

About Bombardier

With more than 60,000 employees across two business segments, Bombardier is a global leader in the transportation industry, developing innovative and game-changing planes and trains. Products and services set new standards in passenger comfort, energy efficiency, reliability and safety. With headquarters in Montreal, Canada, Bombardier has production and development sites in more than 25 countries in the business aviation and rail transportation segments.

About SPIE

The SPIE Group is the independent European market leader in multi-technical services. The company offers a local and wide-ranging service to its customers in industry, in the tertiary sector and in the infrastructure sector. With more than 1,850 employees and 16 branches throughout the country, SPIE Belgium stands for integrated solutions and services in the fields of electrical, mechanical and HVAC engineering as well as energy and communication networks.

Pilz Netherlands Industrial Automation

Havenweg 22

4131 NM Vianen

Netherlands

Telephone: +31 347 320477

E-Mail: info@pilz.nl

Telephone: +31347320477

E-Mail: ts@pilz.nl