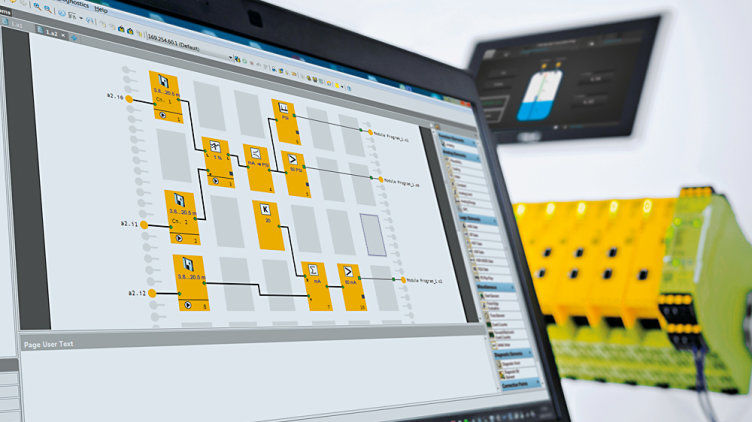

Ease of operation is a persuasive factor in PNOZmulti Configurator. You can use the software tool for planning, configuration, documentation, and commissioning. From version 10.9 you can test your configured user program with the function "Simulation" even before commissioning. In a first release you calculate the logic elements, in further releases you calculate all the elements with the simulation. Elements that are not simulated can be switched to the required state by forcing the outputs. This way, you can implement a simulation of the overall application. The targeted forcing of link elements enables you to simulate your application only in parts. This way you can save the effort of having to define all the inputs!

The state of the inputs and outputs of the configured elements and the connections between the elements are displayed. Active inputs, outputs and connections are highlighted in colour. Non-simulated elements can be found in the tool with the relevant mark.

Features:

- Display of inputs and outputs in variable list: The simulated input and output signals of the elements can be displayed in the variable list.

- Forcing inputs and outputs: The state of a signal can be fixed – irrespective of the user program – (permanent "1" signal or permanent "0" signal). This so-called forcing can be activated or deactivated for all the outputs.

- Simulation for logic element and two operating modes available: Inching and permanent cycle

Find out practically in the video how to use the "Simulation" function for your automation projects! Follow this link

Your operating advantages:

- Simulation opens up significant potential for savings during project design

- Verification of complex logic

- user-friendly aid for detecting faults at an early stage, to analyse and to rectify them

- Simulation helps to reduce risks for man and machine

- Installation costs can be reduced