Safeguards are necessary to protect people as much as possible from hazards that may arise during machine operation - the primary objective is the protection and safety of personnel in the face of mechanical hazards from moving parts on machinery. Technical measures such as guards must be installed, which avoid hazards by simple means, but also meet anti-tampering requirements.

Safeguards and safety devices on plant and machinery

When it comes to safeguards on machinery, there are a wide range of regulations, which take various forms, depending on the country. In the European Union, for example, the manufacturer is obliged to comply with directive 2006/42/EC, the Machinery Directive. There are generally country-specific laws that operators need to consider and observe.

It is not always possible for manufacturers to exclude all risks on a machine without seriously impairing its function or operation. If hazards cannot be designed out and residual risks remain, then the manufacturer must provide safety devices. According to the Machinery Directive, moving, potentially hazardous parts of the machine must be designed and constructed in such a way as to prevent the risk of accidents due to unintended points of contact. If the risk cannot be minimised by design, then "the moving parts of machinery must be fitted with guards or protective devices" (Annex 1, Machinery Directive).

The two basic principles of safeguards

A distinction is made between solutions using guards and protective devices. Guards prevent people accessing or intervening in a machine's danger zone. However, sometimes it is not possible, or even sensible, to select fixed devices such as these, particularly when the risk of tampering increases as a result. Annex 1 of the Machinery Directive requires that the design of a safeguard must prevent it from being easy to render non-operational. Otherwise the machine may not carry a CE mark. In this case, protective devices are a potential approach. These secure the danger zone without any physical separation. Control solutions are often used here, such as safety light curtains in conjunction with a safety controller, for example.

Safeguards

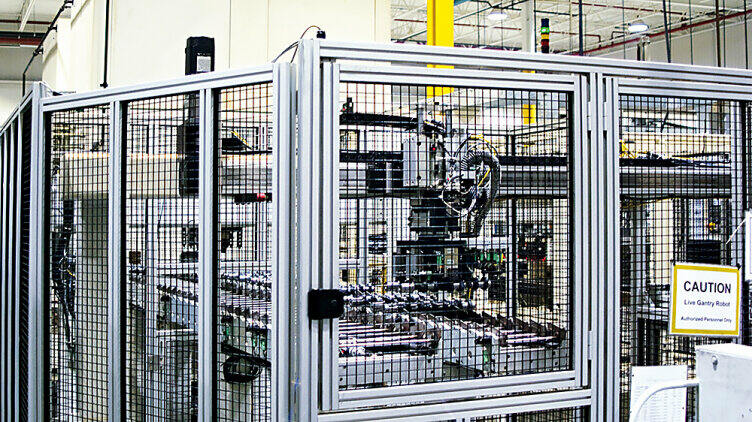

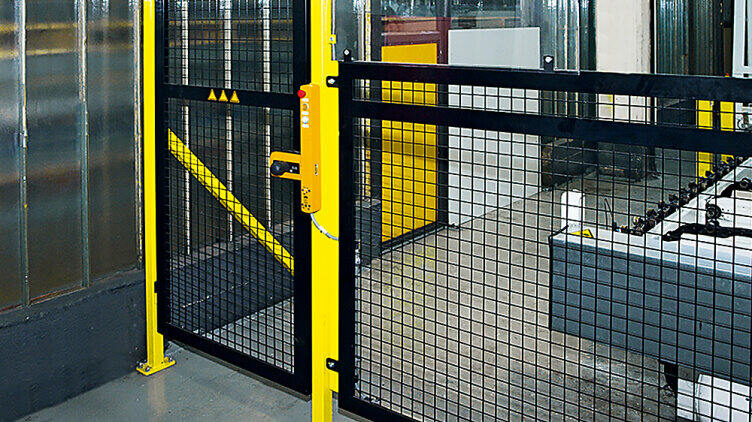

- Fixed guards: Protection is achieved by means of a physical barrier, e.g. through safety fences. The safeguard is permanently installed and visually identifiable, by means of yellow colouring for example.

- Movable guards: the physical barrier is movable, e.g. installed as a safety gate in safety fences or also as covers, flaps and rolling doors. So-called interlocking devices, such as safety switches for example, monitor the protective position. These are used to prevent a hazardous machine function from being carried out.

Protective devices

- Electrosensitive protective equipment (ESPE), optoelectronic protective devices, e.g. light curtains, laser scanners or camera-based protection systems. In addition to classic ESPE, safe radar systems also fall under the category of barrier-free safety solutions.

- Pressure or touch-sensitive protective equipment, e.g. pressure-sensitive mats or edges. This way a hazardous movement can be stopped if an employee stands on the pressure-sensitive mat, for example.

- Location-dependent safeguards, e.g. two-hand pushbuttons or other manually operated control devices or enabling devices. These generally need to be positioned outside of the danger zone. Two-hand control devices commit both of the user's hands when operating a machine, such as a press.

With all measures, sufficiently dimensioned safety distances must be observed to ensure they are effective. The standards EN ISO 13854, EN ISO 13855 and EN ISO 13857 provide the necessary foundations.

Safety devices on a machine must be designed so that work tasks during intended operation are not impeded unnecessarily. At least that's the requirement of the standard EN ISO 12100, which addresses the principles for manufacturing safe machinery.

Tampering of safeguards

Tampering with safeguards renders them ineffective or massively impairs their function. As a consequence, machines are used in a way that was not intended, or protective measures defined by the manufacturer are defeated.

How tampering takes place is irrelevant in the first instance. Accident statistics show that many companies underestimate the risk of tampering. Both the machine manufacturer and operating company are legally obliged to comply with specifications to protect the operator. With this in mind, there are relevant standards that need to be considered and implemented, both in the manufacturer's design of the machine and when operated by the operating company. Should an employee be injured when operating a machine, both parties must expect to face consequences under criminal law. Particularly if the accident was caused by a safeguard that has been tampered with.

Overview of area

Pilz lndustrieelektronik S.L. Safe Automation

Camí Ral, 130 Polígono Industrial Palou Nord

08401 Granollers

Spain

Telephone: +34 938497433

E-Mail: info@pilz.es

Telephone: +49 711 3409 444

E-Mail: support@pilz.com