Pilz safety concepts are based on the individual requirements of the customer. Using our tried and tested methodologies, our safety concepts enable safe interaction between operators or maintenance personnel and machinery - without affecting productivity.

Safety concept for machinery

Combine safety and productivity

The second step to machinery safety: Safety concept

Your requirements

Intelligent and cost-effective safety concept

To remain competitive, as a manufacturer you need an effective, practicable safety concept when using new machinery or converting an existing machine. This must not restrict your machines’ productivity.

You need a safety concept that's individually tailored to your requirements. Of course, its implementation should not involve any unnecessary extra work.

Our services

Based on the machine risk assessment that has already been carried out, the safety concept is where we develop detailed solution proposals for the technical implementation. That way we guarantee the safety of your machinery in accordance with national and international standards as well as your own corporate standards.

The Pilz safety concept (for machinery) considers:

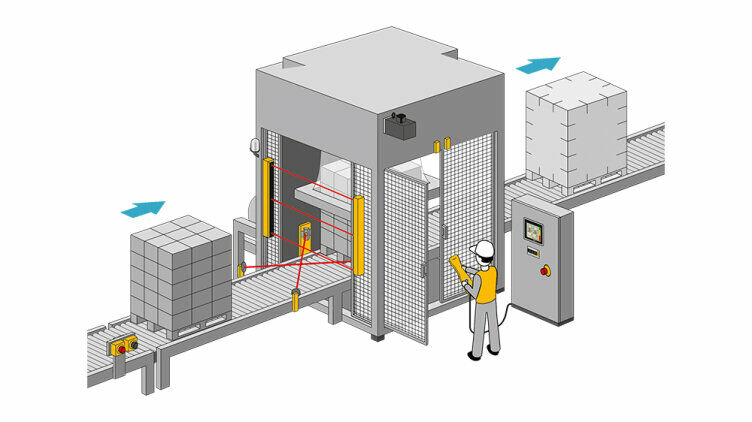

- Use of fixed and movable guards

- Implementation of a safety-related plant and machine controller

- Devices for safe standstill and shutdown of electrical, hydraulic, pneumatic and other potential energy sources

- Detection of workers in danger zones

- Definition of the required performance level (PLr) for safety-related measures or safety functions

Your benefits at a glance

- Compliance and safety

- Improves the productivity of your plant and machinery

- You benefit from our practical engineering experience in implementing safety

- You optimise interaction between staff and machine

- You reduce complexity and costs

- You optimise the scope of maintenance work on your plant and machinery

Your next steps en route to machinery safety

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern

Germany

Telephone: +49 711 3409-0

E-Mail: pilz.gmbh@pilz.de

Americas

- Mexico: +52 55 5572 1300

- Brazil: + 55 11 4942-7032

- Canada: +1 888-315-PILZ (315-7459)

- United States (toll-free): +1 877-PILZUSA (745-9872)

Europe

- Ireland: +353 21 4804983

- Italy: +39 0362 1826711

- Austria: +43 1 7986263-444

- Russia: +7 495 6654993

- Turkey: +90 216 5775552

- Belgium: +32 9 321 75 70

- Sweden: +46 300 13990 / +45 74436332

- Netherlands: +31 347 320477

- Germany: +49 711 3409 444

- Spain: +34 938497433

- Denmark: +45 74436332

- Portugal: +351 229 407 594

- United Kingdom: +44 1536 460866

- France (toll-free): +33 3 88104000

- Switzerland: +41 62 889 79 32

- Finland: +358 10 3224030 / +45 74436332

Asia Pacific

- Australia (toll-free): +61 3 9560 0621 / 1300 723 334

- Japan: +81 45 471 2281

- Taiwan: +886 2 25700068

- Singapore: +65 6829 2920

- China: +86 400-088-3566

- South Korea: +82 31 778 3390

- New Zealand: +64 9 6345350

- Thailand: +66 210 54613